Full resolution (JPEG) - On this page / på denna sida - 1958, H. 4 - An Insulated Cable for Heavy Power Transmission, by Bror Hansson

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

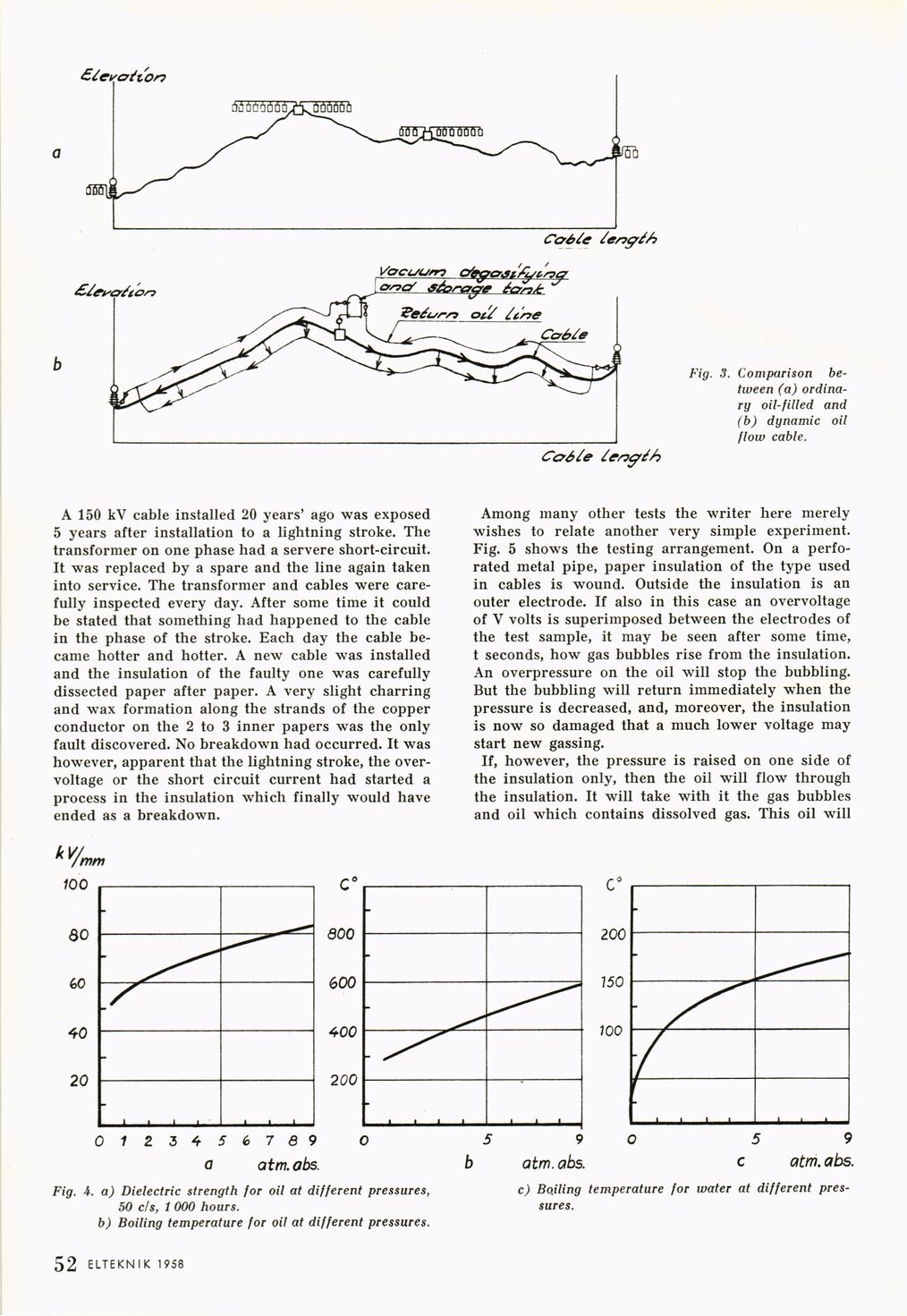

Fig. 3. Comparison

between (a)

ordinary oil-filled and

(b) dynamic oil

flow cable.

A 150 kV cable installed 20 years’ ago was exposed

5 years after installation to a lightning stroke. The

transformer on one phase had a servere short-circuit.

It was replaced by a spare and the line again taken

into service. The transformer and cables were

carefully inspected every day. After some time it could

be stated that something had happened to the cable

in the phase of the stroke. Each day the cable

became hotter and hotter. A new cable was installed

and the insulation of the faulty one was carefully

dissected paper after paper. A very slight charring

and wax formation along the strands of the copper

conductor on the 2 to 3 inner papers was the only

fault discovered. No breakdown had occurred. It was

however, apparent that the lightning stroke, the

over-voltage or the short circuit current had started a

process in the insulation which finally would have

ended as a breakdown.

Among many other tests the writer here merely

wishes to relate another very simple experiment.

Fig. 5 shows the testing arrangement. On a

perforated metal pipe, paper insulation of the type used

in cables is wound. Outside the insulation is an

outer electrode. If also in this case an overvoltage

of V volts is superimposed between the electrodes of

the test sample, it may be seen after some time,

t seconds, how gas bubbles rise from the insulation.

An overpressure on the oil will stop the bubbling.

But the bubbling will return immediately when the

pressure is decreased, and, moreover, the insulation

is now so damaged that a much lower voltage may

start new gassing.

If, however, the pressure is raised on one side of

the insulation only, then the oil will flow through

the insulation. It will take with it the gas bubbles

and oil which contains dissolved gas. This oil will

Fig. 4. a) Dielectric strength for oil at different pressures,

50 c/s, 1 000 hours,

b) Boiling temperature for oil at different pressures.

ELTEKNIK 1958 1 52

c) Boiling temperature for water at different

pressures.

<< prev. page << föreg. sida << >> nästa sida >> next page >>