Full resolution (JPEG) - On this page / på denna sida - N:o 12. Dec. - Sidor ...

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

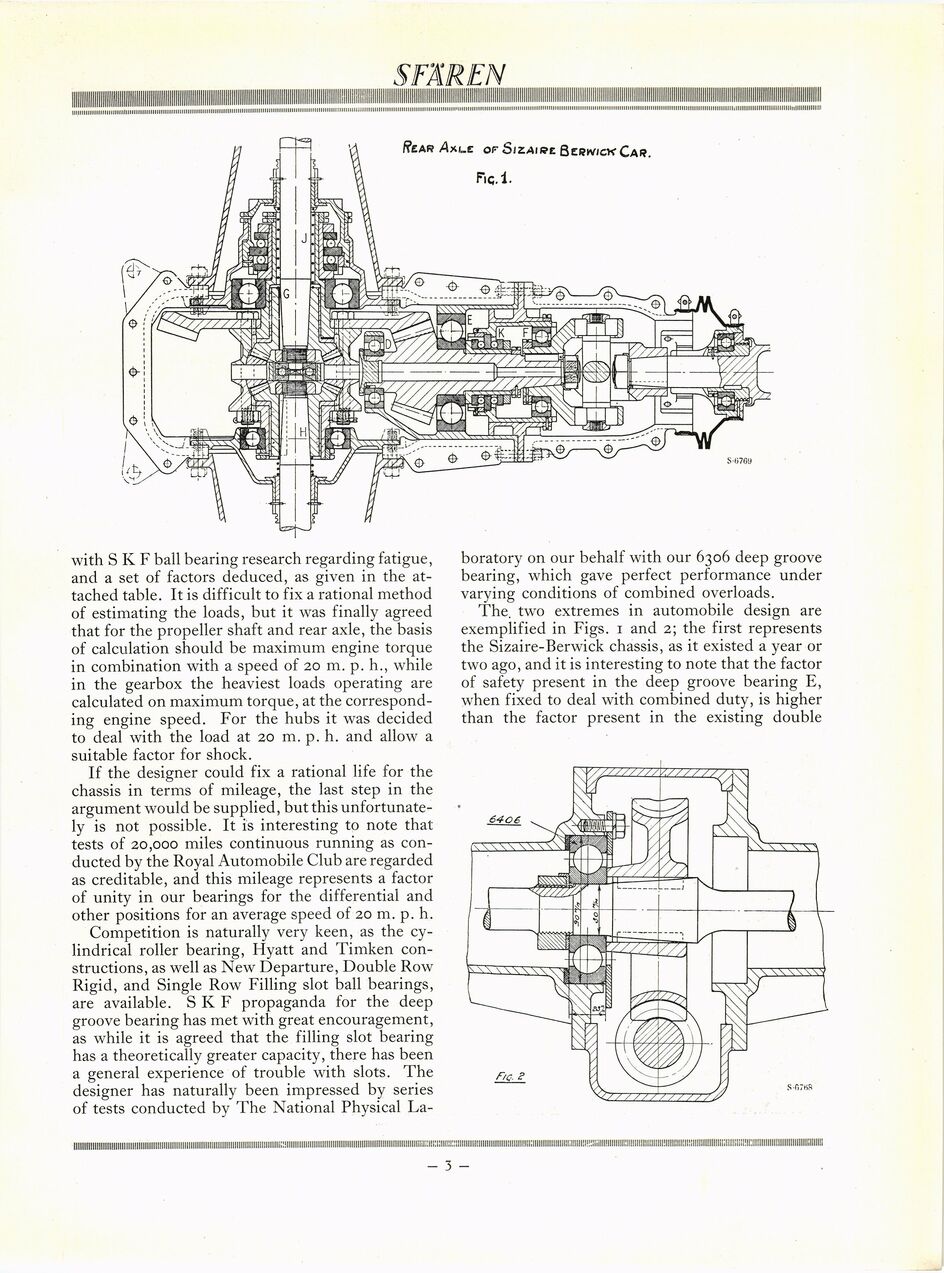

Rear Ahue of Sizaiue Berwick Car.

with SKF ball bearing research regarding fatigue,

and a set of factors deduced, as given in the

attached table. It is difficult to fix a rational method

of estimating the loads, but it was finally agreed

that for the propeller shaft and rear axle, the basis

of calculation should be maximum engine torque

in combination with a speed of 20 m. p. h., while

in the gearbox the heaviest loads operating are

calculated on maximum torque, at the

corresponding engine speed. For the hubs it was decided

to deal with the load at 20 m. p. h. and allow a

suitable factor for shock.

If the designer could fix a rational life for the

chassis in terms of mileage, the last step in the

argument would be supplied, but this

unfortunately is not possible. It is interesting to note that

tests of 20,000 miles continuous running as

conducted by the Royal Automobile Club are regarded

as creditable, and this mileage represents a factor

of unity in our bearings for the differential and

other positions for an average speed of 20 m. p. h.

Competition is naturally very keen, as the

cylindrical roller bearing, Hyatt and Timken

constructions, as well as New Departure, Double Row

Rigid, and Single Row Filling slot ball bearings,

are available. SKF propaganda for the deep

groove bearing has met with great encouragement,

as while it is agreed that the filling slot bearing

has a theoretically greater capacity, there has been

a general experience of trouble with slots. The

designer has naturally been impressed by series

of tests conducted by The National Physical La-

boratory on our behalf with our 6306 deep groove

bearing, which gave perfect performance under

varying conditions of combined overloads.

The. two extremes in automobile design are

exemplified in Figs. 1 and 2; the first represents

the Sizaire-Berwick chassis, as it existed a year or

two ago, and it is interesting to note that the factor

of safety present in the deep groove bearing E,

when fixed to deal with combined duty, is higher

than the factor present in the existing double

<< prev. page << föreg. sida << >> nästa sida >> next page >>