Full resolution (TIFF) - On this page / på denna sida - Fagersta Bruks Aktiebolag

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

FAGERSTA BRUKS AKTIEBOLAG

127

three blast furnaces at Fagersta were started in 1915 and are of the most up-to-date

construction. Their total output is from 35,000 to 40,000 tons. The main part of the pig

iron produced is used by the works themselves for iron and steel-making, but rather large

quantities are also sold to other steel and iron Works. In addition, there is put on the

©/

, which is made in 5 different qualities with a

Siliconpercentage up to 5*5%. This foundry pig iron has obtained general recognition as

being of the same good quality as that characterising all of the Fagersta productions.

THE STEEL WORKS

consist of 7 Siemens-Martin furnaces besides electric furnaces. The first Simens-Martin

furnace was completed in 1884. These furnaces, most of which have a capacity of 10

or 15 tons, have a total output of 60,000 tons of ingots per year. Two electric steel

furnaces manufacture high speed steel and other kinds of special steel.

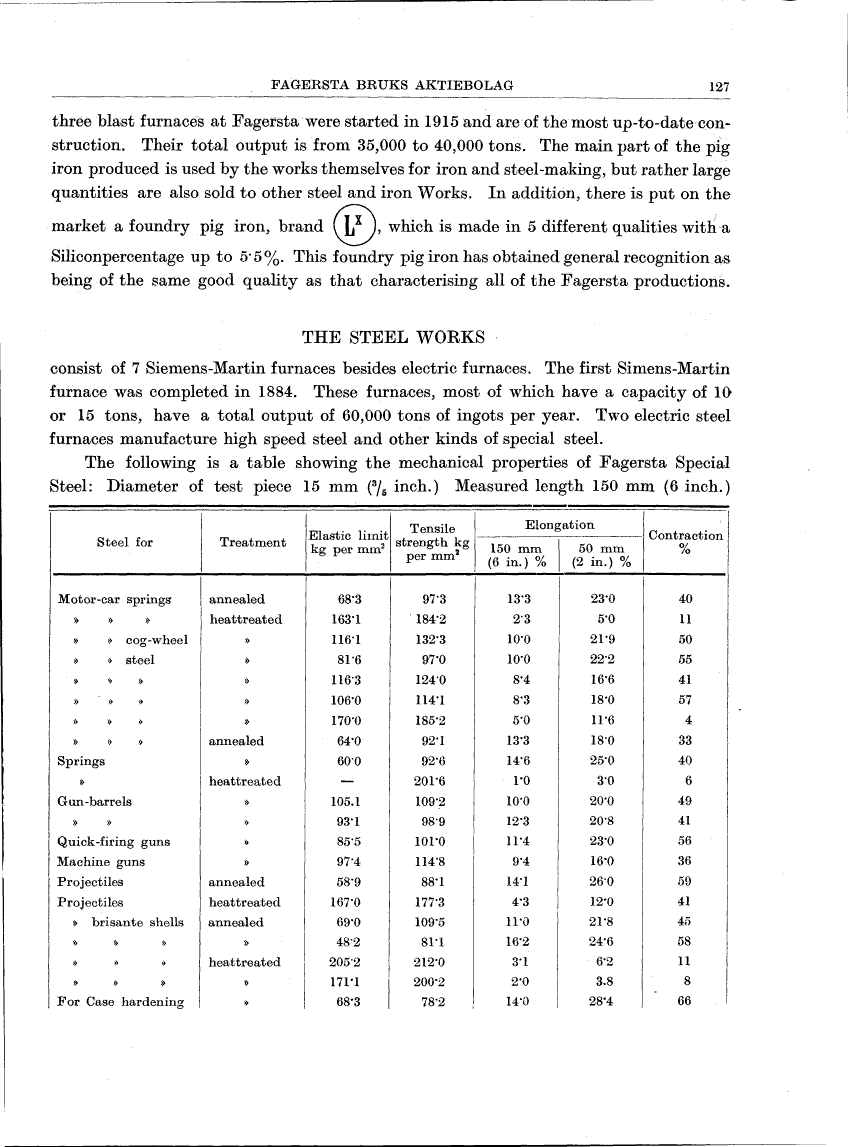

The following is a table showing the mechanical properties of Fagersta Special

Steel: Diameter of test piece 15 mm (3/5 inch.) Measured length 150 mm (6 inch.)

Tor» ail ^ Elongation

Ox , , n A Elastic limit , ?! ,––––––––––––––––––- Contraction

Steel for Treatment , strength kg j mm 50 mm %

___________________________________________________per mm2 (6in>)Q/0 (2 in.) %______________

Motor-car springs annealed 68’3 97’3 13"3 23*0 40

» » » heattreated 1631 184’2 2’3 5’0 11

» » cog-wheel » 1161 132’3 10*0 21’9 50

» » steel »> 81-6 97’0 10*0 22’2 55

» » » » 116’3 124’0 8’4 16*6 41

» » » » 106’0 1141 8’3 18’0 57

» » .> » 170’0 185-2 5-0 11-6 4

» » » annealed 64’0 92’1 13’3 18’0 33

Springs » 60’0 92’6 14’6 25’0 40

» heattreated - 201’6 1*0 3’0 6

Gun-barrels » 105.1 109’2 10*0 20’0 49

» » » 93-1 98’9 12-3 20*8 41

Quick-firing guns » 85’5 101*0 H’4 23’0 56

Machine guns » 97’4 114’8 9’4 16’0 36

Projectiles annealed 58’9 881 14*1 26’0 59

Projectiles heattreated 167’0 177’3 4’3 12*0 41

» brisante shells annealed 69*0 109’5 ll’O 21*8 45

» » » » 48’2 811 16’2 24’6 58

» » » heattreated 205’2 212’0 31 6’2 11

» » » » 1711 200-2 2-0 3.8 8

For Case hardening » 68*3 78’2 14’0 28’4 66 I

<< prev. page << föreg. sida << >> nästa sida >> next page >>