Full resolution (JPEG) - On this page / på denna sida - Second part - IX. Mining Industry and Metal Production - 2. The Iron and Steel Industry. By the late Prof. J. G. Wiborgh - Pig iron

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

720- I

x. mining industry and metal production op sweden.

at least 4/6 of the gas can be taken out at the top of the furnace behind the

cylinder without the use of a closed charging device. This cylinder arrangement

without closed charging device has the advantage of giving a drier and consequently

more effective gas. The figure on page 719 shows a Swedish modern blast ftirnace

open top stack, with cylinder arrangement.

As stated before, closed charging devices are, however, used at some blast

furnaces, but then only at such works where the gas is used for other purposes,

such as Open hearth furnaces, heating of ladles, converters, pit furnaces, etc.,

and also where there are arrangements for drying charcoal.

The charcoal is always charged by certain measures, called

»kolsättning», which however differs from 14 to 16 hectoliters

according to the size of the blast furnace. On each charcoal-charge

the ore on the other hand is charged by weight, altered as

required. At the open top stack the ore is carefully distributed on

the charcoal in such a way that a certain weight is charged in

a ring close to the wall, called »mursättning», while the rest of

the ore is evenly distributed on the charcoal. With a closed

charging device it is scarcely possible to distribute the ore as

well as in an open top stack, but the devices here in use are

in that respect superior to those abroad.

Two different types of charging devices are in use, one by

Mr. Charleville, the other by Dr. H. Tholander.

Charleville’a charging device consists of a hopper in

which a bell is attached. The angular space between this bell

and the hopper can be closed or opened by lowering or

raising a ring of a triangular cross-section. When the

apparatus is closed, two ring-shaped compartments are formed, the

one between the ring and the bell, the other between the ring

and the hopper. When the ring is lowered, the ore which is

in the inner compartment falls towards the center of the stack,

but the ore in the outer compartment towards the wall of the

stack. The apparatus is in design very similar to the one

constructed by the Englishman Coingts, which has been in use at

several foreign blast furnaces.

Tholander s charging device consists of the usual outer

ring or hopper and inside this a small sheet-iron hopper, which

rests on the former by means of a vertical flange. The smaller

hopper is kept closed by a bell, which by means of short chains

is connected with the former in such a way that after the bell has been raised

a certain distance, the smaller hopper has to follow. If the charcoal and part of

the ore be charged in the inner hopper and the rest of the ore between this and

the outer hopper, the bell then being raised, the first part of the charge falls towards

the center, and with the further raising of the bell the hopper, as before stated, is

also raised and the balance of ore falls towards the wall. In order better to distribute

the ore in the position desired a vertical cylinder is suspended from the funnel.

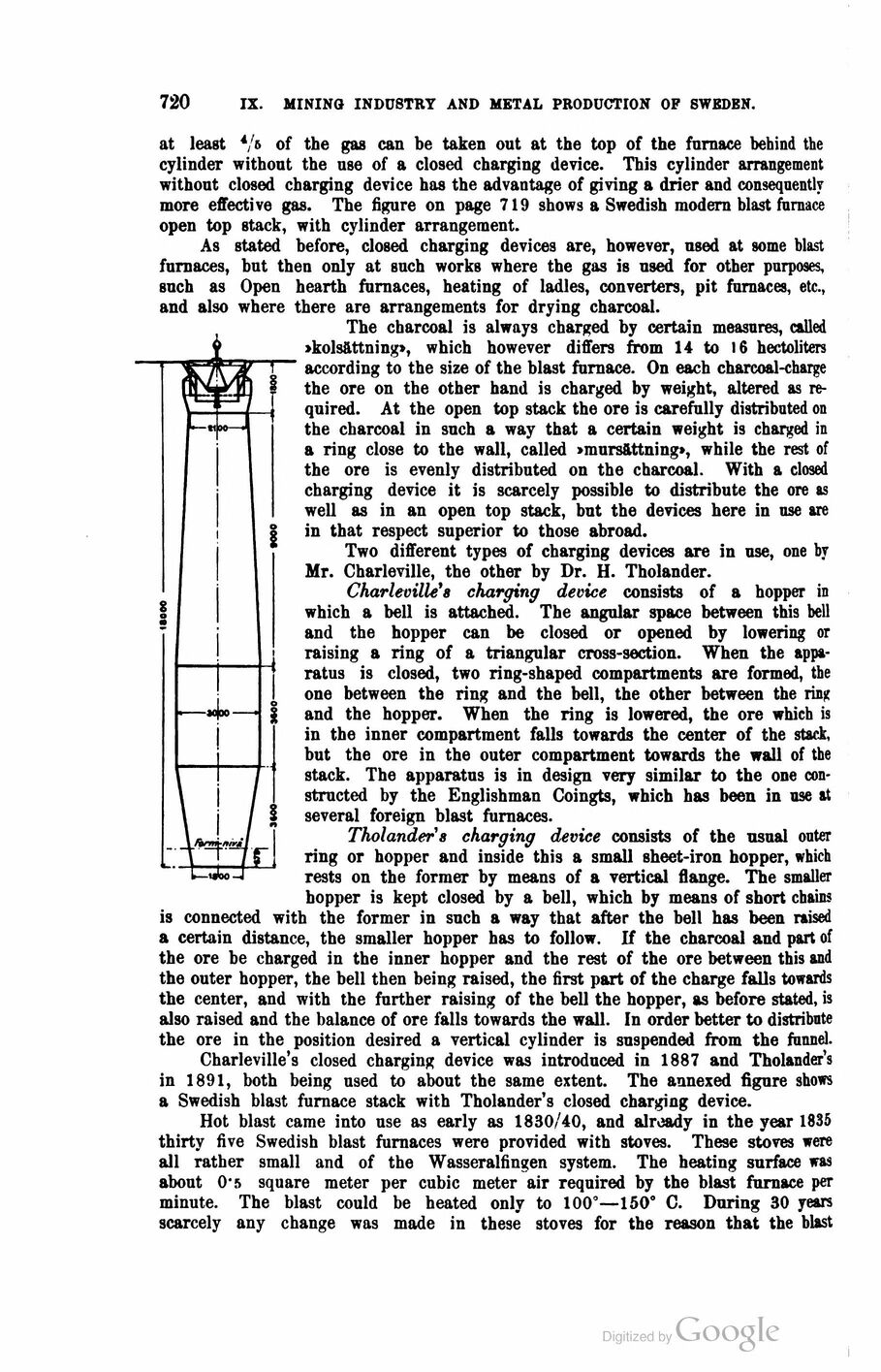

Charleville’s closed charging device was introduced in 1887 and Tholander’s

in 1891, both being used to about the same extent. The annexed figure shows

a Swedish blast furnace stack with Tholander’s closed charging device.

Hot blast came into use as early as 1830/40, and already in the year 1835

thirty five Swedish blast furnaces were provided with stoves. These stoves were

all rather small and of the Wasseralfingen system. The heating surface was

about 0"s square meter per cubic meter air required by the blast furnace per

minute. The blast could be heated only to 100°—150° C. During 30 years

scarcely any change was made in these stoves for the reason that the blast

<< prev. page << föreg. sida << >> nästa sida >> next page >>