Full resolution (JPEG) - On this page / på denna sida - Second part - IX. Mining Industry and Metal Production - 2. The Iron and Steel Industry. By the late Prof. J. G. Wiborgh - Pig iron

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

wrought iron.

721

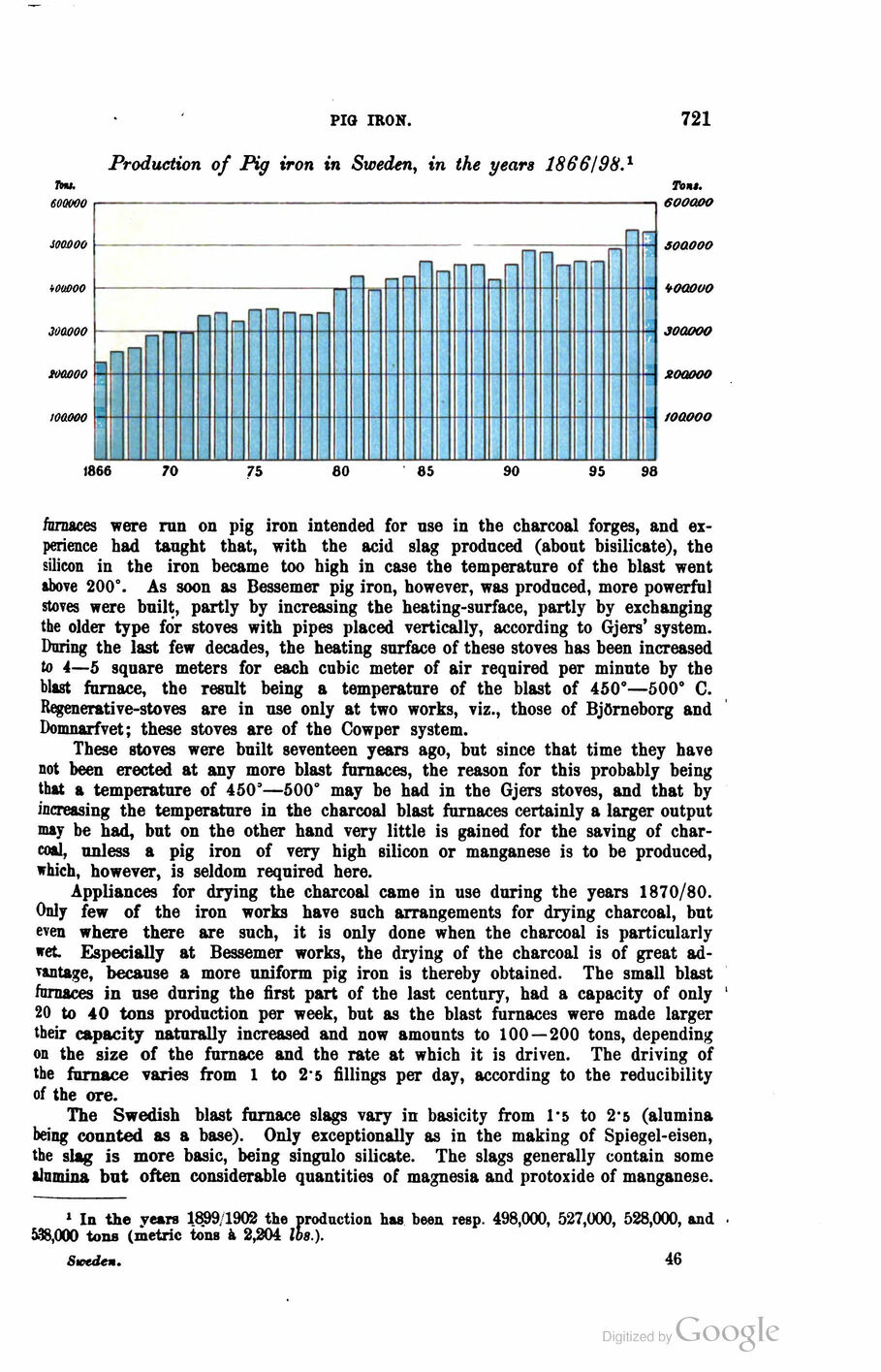

Production of Pig iron in Sweden, in the years 1866/98.*

7m. Tom.

fnrnaces were run on pig iron intended for use in the charcoal forges, and

experience had taught that, with the acid slag produced (about bisilicate), the

silicon in the iron became too high in case the temperature of the blast went

above 200°. As soon as Bessemer pig iron, however, was produced, more powerful

stoves were built, partly by increasing the heating-surface, partly by exchanging

the older type for stoves with pipes placed vertically, according to Gjers’ system.

During the last few decades, the heating surface of these stoves has been increased

to 4—5 square meters for each cubic meter of air required per minute by the

blast furnace, the result being a temperature of the blast of 450°—500° C.

Regenerative-stoves are in use only at two works, viz., those of Björneborg and

Domnarfvet; these stoves are of the Cowper system.

These stoves were built seventeen years ago, but since that time they have

not been erected at any more blast furnaces, the reason for this probably being

that a temperature of 450°—500° may be had in the Gjers stoves, and that by

increasing the temperature in the charcoal blast furnaces certainly a larger output

may be had, but on the other hand very little is gained for the saving of

charcoal, unless a pig iron of very high silicon or manganese is to be produced,

which, however, is seldom required here.

Appliances for drying the charcoal came in use during the years 1870/80.

Only few of the iron works have such arrangements for drying charcoal, but

even where there are such, it is only done when the charcoal is particularly

"et. Especially at Bessemer works, the drying of the charcoal is of great

advantage, because a more uniform pig iron is thereby obtained. The small blast

fnrnaces in use during the first part of the last century, had a capacity of only ’

20 to 40 tons production per week, but as the blast furnaces were made larger

their capacity naturally increased and now amounts to 100—200 tons, depending

on the size of the furnace and the rate at which it is driven. The driving of

the furnace varies from 1 to 2 5 fillings per day, according to the reducibility

of the ore.

The Swedish blast furnace slags vary in basicity from 1*5 to 2-5 (alumina

being counted as a base). Only exceptionally as in the making of Spiegel-eisen,

the slag is more basic, being singulo silicate. The slags generally contain some

alumina but often considerable quantities of magnesia and protoxide of manganese.

1 In the veare 1899/1902 the production has been resp. 498,000, 527,000, 528,000, and

538,000 tons (metric tons à 2,204 lbs.).

Sweden. 46

<< prev. page << föreg. sida << >> nästa sida >> next page >>