Full resolution (JPEG) - On this page / på denna sida - Second part - IX. Mining Industry and Metal Production - 2. The Iron and Steel Industry. By the late Prof. J. G. Wiborgh - Wrought iron

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

726- ix. mining industry and metal production op sweden.

During the quinquennial periods of 1861/1900, the exports of blooms

and rough bars have been, in yearly averages, respectively 2,503, 7,042,

11,146, 11,313, 7,953, 12,877, 11,578, and 21,270 metric tons; in 1900, the

amount was, as is stated above, 21,897 tons. Hence, a rather great

increase is to be noted concerning this article.

In like manner as above, where treating of pig iron, an historical

account may here be given of the method in the production of bar

iron, the comparatively detailed treatment devoted to which may in

this case, as also in the former, find its explanation from the very

prominent position which the iron production has always held in the

history of Swedish industry.

Refining in hearths. The oldest well known method of making

wrought iron from pig iron by means of refining in hearths was the

so-called »German forging», which was introduced in the country at the

beginning of the seventeenth century.

This refining was done in an open hearth of heavy cast iron slabs, in which

pig iron low in silicon was melted with charcoal, and after being cooled off

with water ponred into the hearth, was broken loose from the bottom of the

hearth by means of iron bars, and was then remelted, this process sometimes

being repeated several times. By such oxidizing meltings, the charcoal and silicon

in the pig iron were removed, and a lump of soft and slangy iron was obtained.

This was taken out of the hearth, put under a heavy hammer run by water,

and cut up into blooms. In order to get a more compact and less slasrøy iron

these blooms were reheated, which was done in the same hearths, while fresh

pig iron was melting, and were afterwards forged by hammers into bars.

For one ton of bar iron over 200 hectoliters of charcoal were consumed, and

only two or three tons could be produced per week in a German hearth. The

waste amounted to 18 %.

In several other countries, much the same method of refining was used, hot

was gradually subjected to improvements.

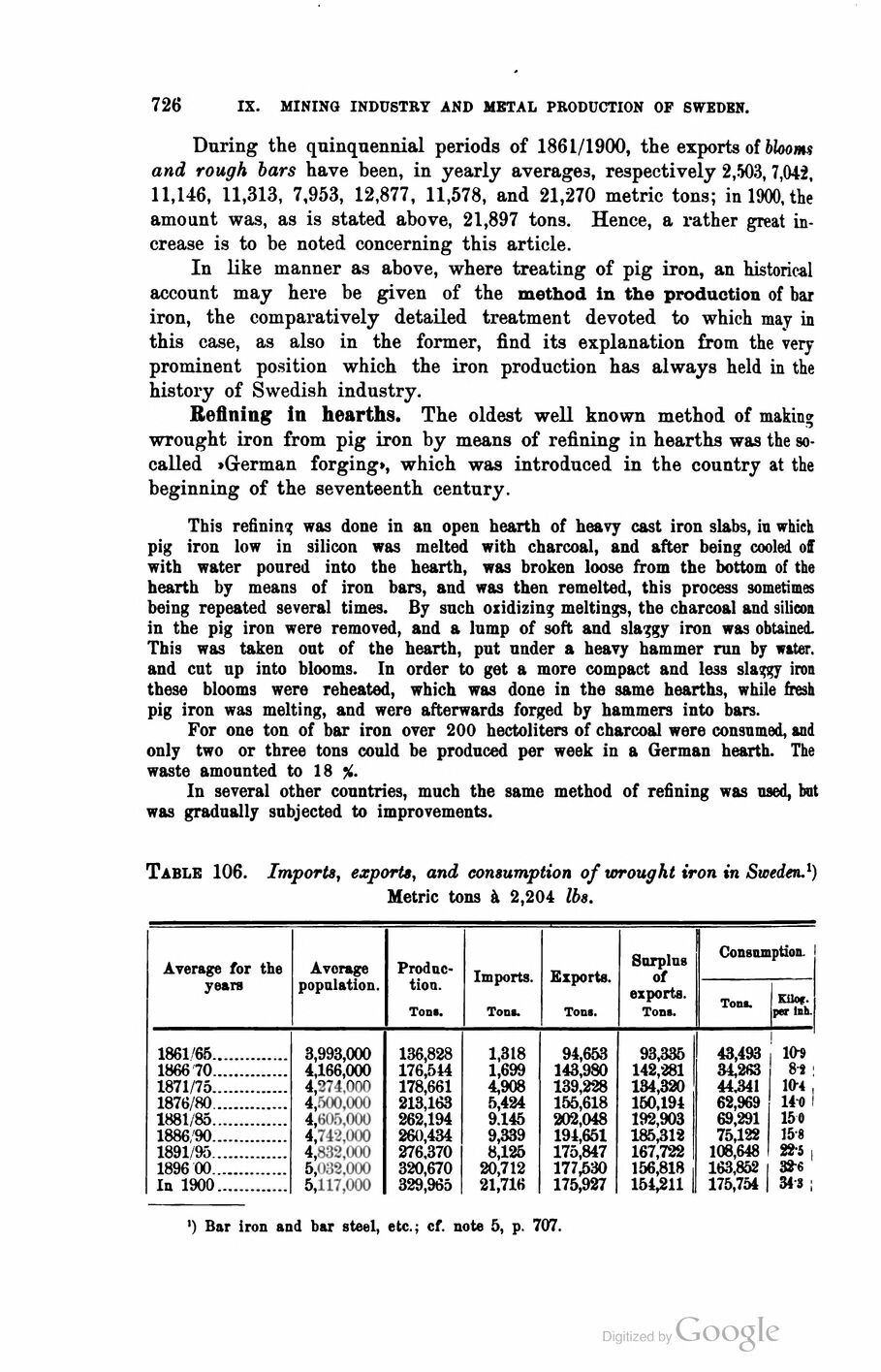

Table 106. Imports, exports, and consumption of wrought iron in Sweden.1)

Metric tons à 2,204 lbs.

Average for the

years

Average

population.

[-Production.-]

{+Produc-

tion.+}

Tom.

Imports.

Tona.

Exports.

Tom.

Surplus

of

exports.

Ton».

Consumption.

Tons.

per inh.

1861/65.............. 3,993,000 136,828 1,318 94,653 93,335 43,493 10-9

1866 70.............. 4,166,000 176,544 1,699 143,980 142,281 34,263 81

1871/75.............. 4,274.000 178,661 4,908 139,228 134,320 44.341 10*4 ,

1876/80.............. 4,500,000 213,163 5,424 155,618 150,194 62,969 140 t

1881/85............................4,605.000 262,194 9.145 202,048 192,903 69,291 150

1886/90............................4,742,(XJO 260,434 9,339 194,651 185,312 75,122 158

1891/95............................4,832,000 276,370 8,125 175,847 167,722 | 108,648 22-51

1896 00............................5,032.000 320,670 20,712 177,530 156,818 , 163,852 i 3*6

In 1900 ............. 5,117,000 329,965 21,716 175,927 154,211 | 175,754 | 34 3 ;

’) Bar iron and bar steel, etc.; cf. note 5, p. 707.

<< prev. page << föreg. sida << >> nästa sida >> next page >>