Full resolution (JPEG) - On this page / på denna sida - IV. Forestry - 2. Forest Industries. By E. Arosenius

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

sawing and export. 211

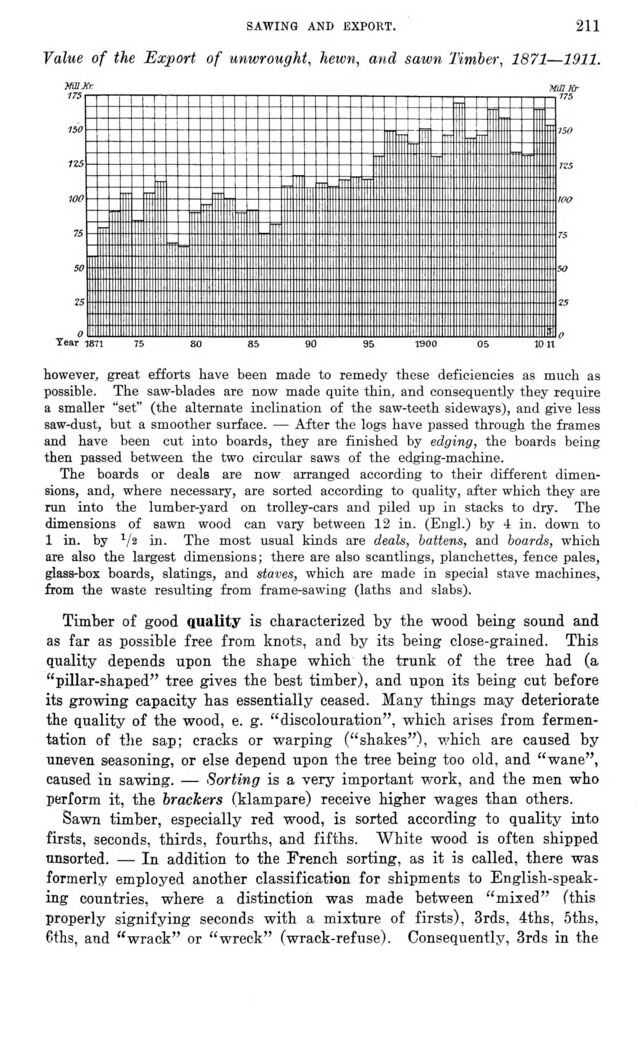

Value of the Export of unwrought, hewn, and sawn Timber, 1871—1911.

miJCr mi Kr

773 r-n– i ■ i i i i i i i i i ■ i i i i i i i i i . i ........1 i i 1175

however, great efforts have been made to remedy these deficiencies as much as

possible. The saw-blades are now made quite thin, and consequently they require

a smaller "set" (the alternate inclination of the saw-teeth sideways), and give less

saw-dust, but a smoother surface. — After the logs have passed through the frames

and have been cut into boards, they are finished by edging, the boards being

then passed between the two circular saws of the edging-machine.

The boards or deals are now arranged according to their different

dimensions, and, where necessary, are sorted according to quality, after which they are

run into the lumber-yard on trolley-cars and piled up in stacks to dry. The

dimensions of sawn wood can vary between 12 in. (Engl.) by 4 in. down to

1 in. by V2 in. The most usual kinds are deals, battens, and boards, which

are also the largest dimensions; there are also scantlings, planchettes, fence pales,

glass-box boards, slatings, and staves, which are made in special stave machines,

from the waste resulting from frame-sawing (laths and slabs).

Timber of good Quality is characterized by the wood being sound and

as far as possible free from knots, and by its being close-grained. This

quality depends upon the shape which the trunk of the tree had (a

"pillar-shaped" tree gives the best timber), and upon its being cut before

its growing capacity has essentially ceased. Many things may deteriorate

the quality of the wood, e. g. "discolouration", which arises from

fermentation of the sap; cracks or warping ("shakes"), which are caused by

uneven seasoning, or else depend upon the tree being too old. and "wane",

caused in sawing. — Sorting is a very important work, and the men who

perform it, the brackers (klampare) receive higher wages than others.

Sawn timber, especially red wood, is sorted according to quality into

firsts, seconds, thirds, fourths, and fifths. White wood is often shipped

unsorted. — In addition to the French sorting, as it is called, there was

formerly employed another classification for shipments to

English-speaking countries, where a distinction was made between "mixed" (this

properly signifying seconds with a mixture of firsts), 3rds, 4ths, 5ths,

6ths, and "wrack" or "wreck" (wrack-refuse). Consequently, 3rds in the

<< prev. page << föreg. sida << >> nästa sida >> next page >>