Full resolution (JPEG) - On this page / på denna sida - VI. Mining and Metallurgical Industry. General Survey. By C. Sahlin - 2. Iron and Steel Industry. By J. A. Leffler

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

-290

vi. mining and metallurgical industry.

is from 90 to 120 millimeters of mercury. Nowadays hot-blast is always used:

it is obtained from a small hot-blast stove, which lies in the path of the esca^

ping gases.

The main features of the Lancashire process are as follows:

Each charge consists of from 140 to 150 kilograms of iron in flat pigs,

previously heated in the heating chamber. These pigs are raked down into the

hearth, which is filled with charcoal to a level slightly above that of the

tuyeres, whereupon they are covered over with charcoal, the blast is

turned on and the smelting begins. As the charcoal burns away, fresh coal is

thrown on. From time to time a little water is sprinkled on the coals with a

dipper, in order to relieve the workman from the intense heat, and also to

prevent the carbonic oxide from burning away before it enters the heating

chamber. The charcoal employed has previously been washed free from sand

and earth; this obviously renders the charcoal moist, but is actually an

advantage for the process.

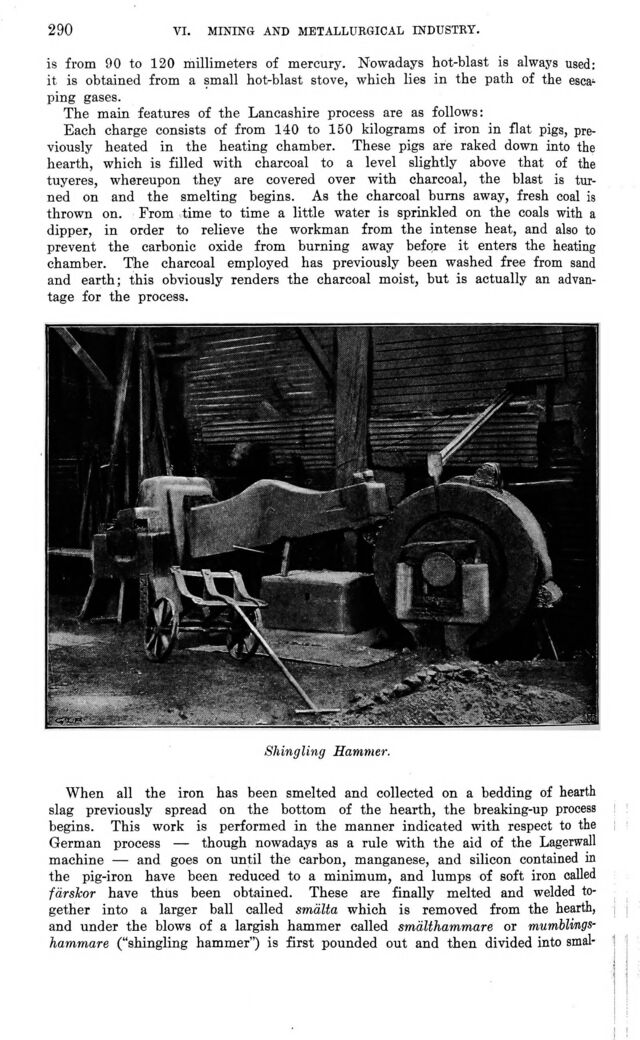

Shingling Hammer.

When all the iron has been smelted and collected on a bedding of hearth

slag previously spread on the bottom of the hearth, the breaking-up process

begins. This work is performed in the manner indicated with respect to the

German process — though nowadays as a rule with the aid of the Lagerwall

machine — and goes on until the carbon, manganese, and silicon contained in

the pig-iron have been reduced to a minimum, and lumps of soft iron called

färskor have thus been obtained. These are finally melted and welded

together into a larger ball called smälta which is removed from the hearth,

and under the blows of a largish hammer called smälthammare or

mumblingshammare ("shingling hammer") is first pounded out and then divided into smal-

<< prev. page << föreg. sida << >> nästa sida >> next page >>