Full resolution (JPEG) - On this page / på denna sida - Transducer Properties in Magnetostrictive Delay Lines, ny Gunnar Svala

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

Fig. Calculated response of a delay line for square

current pulse of amplitude I0 ond length r, equal

to the transit time of each transducer. Broken line

illustrates ideal case of unlimited bandwidth, full

line corresponds to sharp cut-off at f — lit.

eqs. (3) and (4) yl= jcor. After some simplifications

eq. (17) can then he written in operator form

U = " 2T*(1 ~ 2 + 2P T) ’ 7 (18)

and we find immediately that the voltage on the

receiver for a unit step current on the transmitter

side consists of a negative pulse of amplitude A2/2 Z/{

and length r, immediately followed by a positive

pulse of equal length and amplitude. It will be

readily realized that the feeding of a rectangular

current pulse of length r to the transmitter gives

the most favourable superposition of the two unit

steps, so that the receiver pulse will have the

appearance seen in fig. 4 (broken lines). It can be easily

shown, furthermore, that the positive amplitude

A1 j7.1 of the resulting pulse can be calculated as

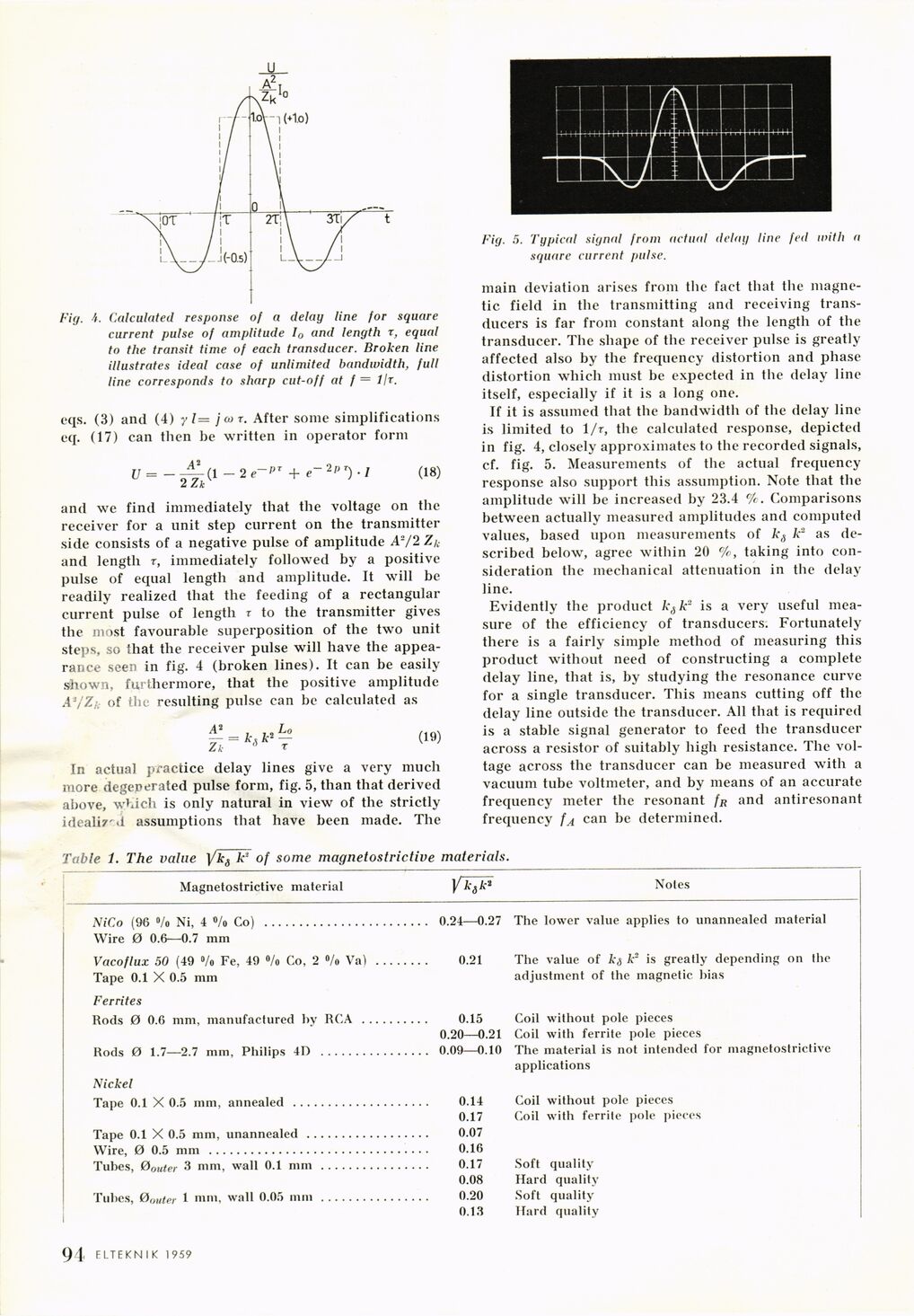

In actual practice delay lines give a very much

more degenerated pulse form, fig. 5, than that derived

above, which is only natural in view of the strictly

idealized assumptions that have been made. The

Fig. 5. Typical signal from actual delay line fed with a

square current pulse.

main deviation arises from the fact that the

magnetic field in the transmitting and receiving

transducers is far from constant along the length of the

transducer. The shape of the receiver pulse is greatly

affected also by the frequency distortion and phase

distortion which must be expected in the delay line

itself, especially if it is a long one.

If it is assumed that the bandwidth of the delay line

is limited to 1/r, the calculated response, depicted

in fig. 4, closely approximates to the recorded signals,

cf. fig. 5. Measurements of the actual frequency

response also support this assumption. Note that the

amplitude will be increased by 23.4 %. Comparisons

between actually measured amplitudes and computed

values, based upon measurements of ks k2 as

described below, agree within 20 taking into

consideration the mechanical attenuation in the delay

line.

Evidently the product ksk2 is a very useful

measure of the efficiency of transducers. Fortunately

there is a fairly simple method of measuring this

product without need of constructing a complete

delay line, that is, by studying the resonance curve

for a single transducer. This means cutting off the

delay line outside the transducer. All that is required

is a stable signal generator to feed the transducer

across a resistor of suitably high resistance. The

voltage across the transducer can be measured with a

vacuum tube voltmeter, and by means of an accurate

frequency meter the resonant /r and antiresonant

frequency can be determined.

Table i. The value Ykö k1 of some magnetostrictive materials.

Magnetostrictive material Vk6k* Notes

NiCo (96 °/o Ni, 4 °/o Co) .................... Wire 0 0.6—0.7 mm 0.24—0.27 The lower value applies to unannealed material

Vacoflux 50 (49 %> Fe, 49 °/o Co, 2 %> Va) Tape 0.1 X 0.5 mm 0.21 The value of k,5 k2 is greatly depending on the adjustment of the magnetic bias

Ferrites

Rods 0 0.6 mm, manufactured bv RCA ...... ____ 0.15 Coil without pole pieces

0.20—0.21 Coil with ferrite pole pieces

Rods 0 1.7—2.7 mm, Philips 4D ............ 0.09—0.10 The material is not intended for magnetostrictive applications

Nickel

Tape 0.1 X 0.5 mm, annealed ................ 0.14 Coil without pole pieces

0.17 Coil with ferrite pole pieces

Tape 0.1 X 0.5 mm, unannealed .............. ____ 0.07

Wire, 0 0.5 mm ............................ ____ 0.16

Tubes, Øouter 3 mm, wall 0.1 mm ............ ____ 0.17 Soft quality

0.08 Hard quality

Tubes, Øonter 1 mm, wall 0.05 mm............ 0.20 Soft quality

0.13 Hard quality

] 94 ELTEKN I K 1959

<< prev. page << föreg. sida << >> nästa sida >> next page >>