Full resolution (JPEG) - On this page / på denna sida - N:o 6. Juni - Sidor ...

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

på denna ville han anföra de med »S K F» märkta

cigaretter, som deltagarna i lunchen bjudits på.

Han tog för givet, att dessa cigaretter skulle bliva

lika uppskattade som alla övriga artiklar med

samma märke.

Lunchen avslutades med ett fyrfaldigt leve för

SKF, varefter gästerna begåvo sig i väg, en del

till Windsor för att bese Kungl. Slottet, de övriga

till Konungens Garden Party i Buckingham Palace.

S. J. Aries.

SYNOPSIS OF CONTENTS

Power Savings by means of Antifriction

Bearings

As the question of power economy with the use-of

antifriction bearings is very extensive, the author has had to

confine himself to treat in detail of but two branches

where anti-friction bearings have been introduced.

Railways are the first to be discussed. In Sweden, where

during the last ten years extensive trials with ball and

roller bearings in locomotives and railway carriages have

been carried out, it has been found that the running

security with these types of bearings is practically absolute.

It has been ascertained that the following average savings

in coal consumption are possible in a country with a

climate resembling that of Sweden:—

For locomotives of the highest efficiency 4.25

kilogrammes of coal per 1000 tons kilometres, and up to 5

kilogrammes of coal per 1000 tons kilometres for locomotives

of less efficiency.

This saving represents 11% to 14% of the amount of

coal necessary for the propulsion of trains.

Hot rolling mills for iron and steel are the second branch.

Trials with these machines show a power saving of no less

than 45%. If the price of power is as low as 2,61 ore per

K. w. hour, this represents no less than Kr. 2: 10 per ton

of steel wire.

Finally, the author states that in these two branches

the bearing conditions are similar, and that the economy

figures can therefore be regarded as quite reliable. In other

branches this is not the case, as the bearing conditions

vary considerably. He gives, however, in the following

table the greatest and lowest savings effected during tests,

and the average figure suggested by the experience of

SKF engineers.

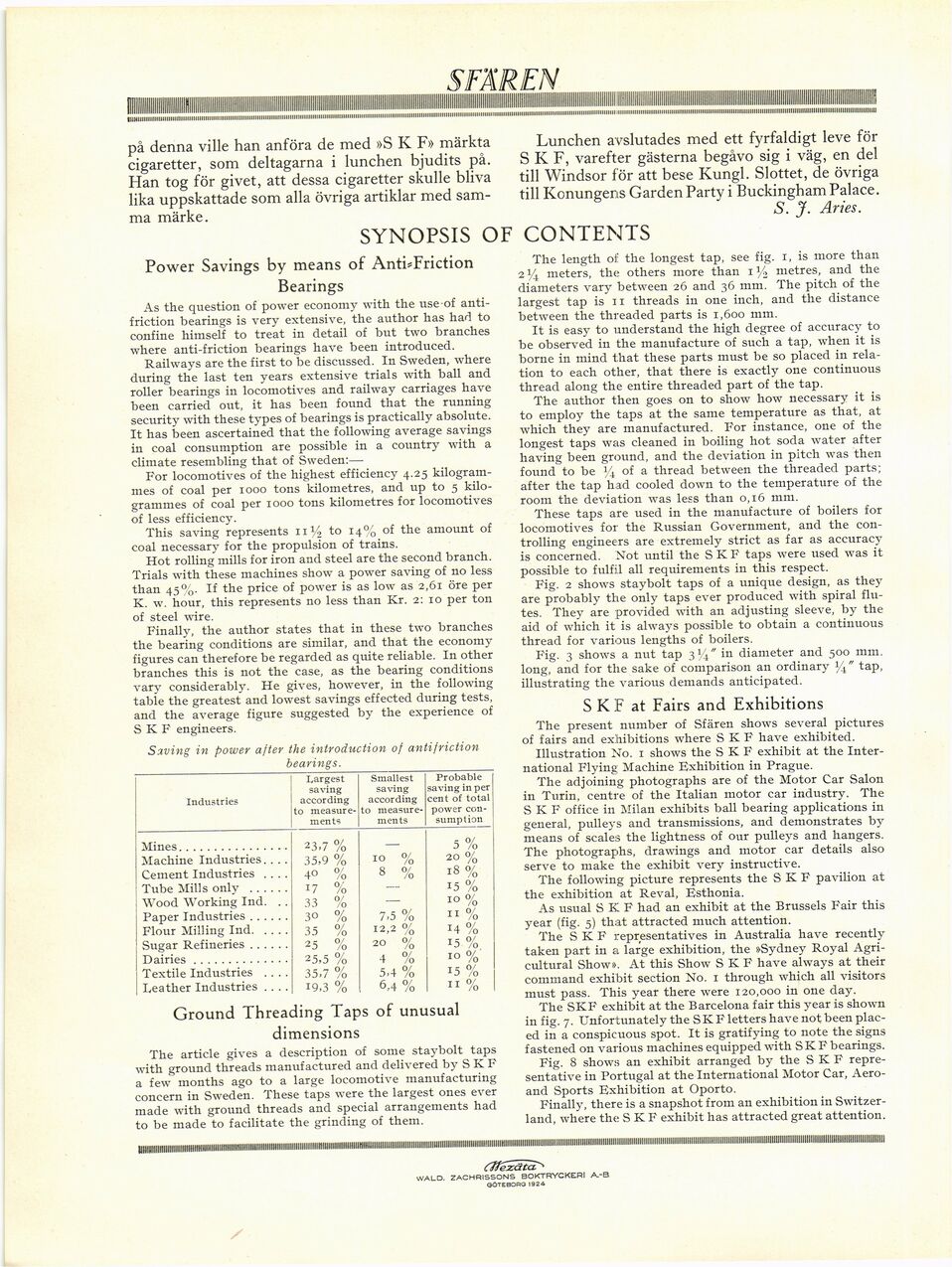

Saving in power after the introduction of antifriction

bearings.

Industries Largest saving according to

measurements Smallest saving according to

measurements Probable saving in per cent of total power

consumption

Mines................ 23,7 /o _ 5 /o

Machine Industries.... 35,9 /o 10 % 20 0/ /o

Cement Industries .... 40 % 8 % 18 0/ /o

Tube Mills only ...... 17 % 15 /o

Wood Working Ind. . . 33 /o •— 10 /o

Paper Industries...... 3° 0/ /o 7,5 % 11 /o

Flour Milling Ind..... 35 /o 12,2 % 14 /o

Sugar Refineries...... 25 0/ /o 20 o/o 15 0/ /o

Dairies.............. 25,5 /o 4 % 10 /o

Textile Industries .... 35.7 0/ /o 5,4 % 15 0/ /o

Leather Industries .... 19.3 /o 6,4 % 11 /o

Ground Threading Tap s of unusual

dimensions

The article gives a description of some staybolt taps

with ground threads manufactured and delivered by S K F

a few months ago to a large locomotive manufacturing

concern in Sweden. These taps were the largest ones ever

made with ground threads and special arrangements had

to be made to facilitate the grinding of them.

The length of the longest tap, see fig. 1, is more than

2 y4 meters, the others more than 1 y2 metres, and the

diameters vary between 26 and 36 mm. The pitch of the

largest tap is 11 threads in one inch, and the distance

between the threaded parts is 1,600 mm.

It is easy to understand the high degree of accuracy to

be observed in the manufacture of such a tap, when it is

borne in mind that these parts must be so placed in

relation to each other, that there is exactly one continuous

thread along the entire threaded part of the tap.

The author then goes on to show how necessary it is

to employ the taps at the same temperature as that, at

which they are manufactured. For instance, one of the

longest taps was cleaned in boiling hot soda water after

having been ground, and the deviation in pitch was then

found to be % of a thread between the threaded parts;

after the tap had cooled down to the temperature of the

room the deviation was less than 0,16 mm.

These taps are used in the manufacture of boilers for

locomotives for the Russian Government, and the

controlling engineers are extremely strict as far as accuracy

is concerned. Not until the SKF taps were used was it

possible to fulfil all requirements in this respect.

Fig. 2 shows staybolt taps of a unique design, as they

are probably the only taps ever produced with spiral

flutes. They are provided with an adjusting sleeve, by the

aid of which it is always possible to obtain a continuous

thread for various lengths of boilers.

Fig. 3 shows a nut tap 3%" in diameter and 500 mm.

long, and for the sake of comparison an ordinary tap,

illustrating the various demands anticipated.

SKF at Fairs and Exhibitions

The present number of Sfären shows several pictures

of fairs and exhibitions where SKF have exhibited.

Illustration No. 1 shows the SKF exhibit at the

International Flying Machine Exhibition in Prague.

The adjoining photographs are of the Motor Car Salon

in Turin, centre of the Italian motor car industry. The

SKF office in Milan exhibits ball bearing applications in

general, pulleys and transmissions, and demonstrates by

means of scales the lightness of our pulleys and hangers.

The photographs, drawings and motor car details also

serve to make the exhibit very instructive.

The following picture represents the SKF pavilion at

the exhibition at Reval, Esthonia.

As usual SKF had an exhibit at the Brussels Fair this

year (fig. 5) that attracted much attention.

The SKF representatives in Australia have recently

taken part in a large exhibition, the »Sydney Royal

Agricultural Show». At this Show SKF have always at their

command exhibit section No. 1 through which all visitors

must pass. This year there were 120,000 in one day.

The SKF exhibit at the Barcelona fair this year is shown

in fig. 7. Unfortunately the SKF letters have not been

placed in a conspicuous spot. It is gratifying to note the signs

fastened on various machines equipped with SKF bearings.

Fig. 8 shows an exhibit arranged by the SKF

representative in Portugal at the International Motor Car,

Aero-and Sports Exhibition at Oporto.

Finally, there is a snapshot from an exhibition in

Switzerland, where the SKF exhibit has attracted great attention.

WALD. ZACHRISSONS BOKTRYCKERI A.-B

©OTEBORG 1924

<< prev. page << föreg. sida << >> nästa sida >> next page >>