Full resolution (JPEG) - On this page / på denna sida - Sidor ...

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

Doc. 205. ] 47

SWEDENBORG’S TRAVELS IN 1733.

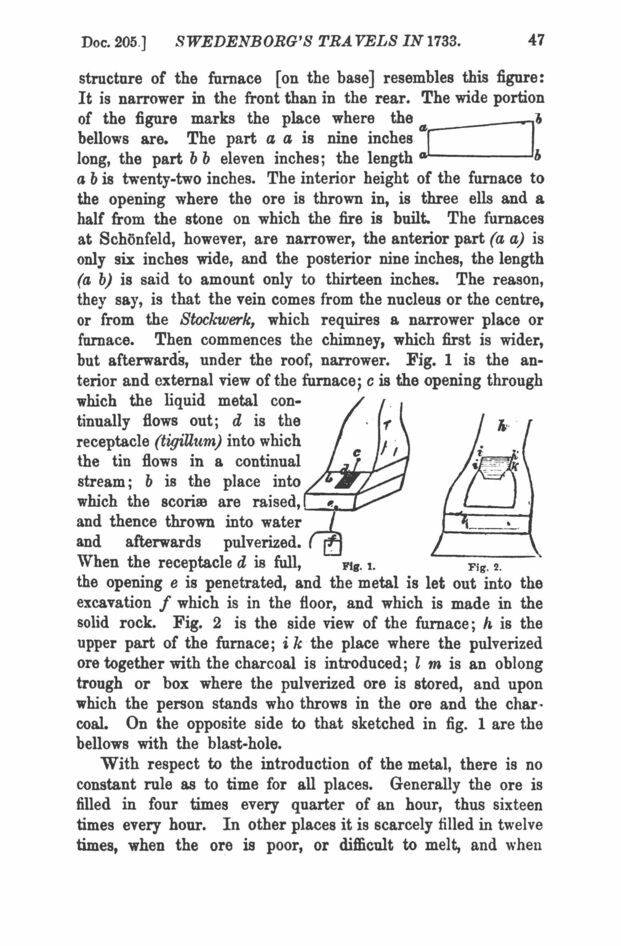

structure of the furnace [on the base] resembles this figure:

It is narrower in the front than in the rear. The wide portion

of the figure marks the place where the b

bellows are. The part a a is nine inches

long, the part bb eleven inches ; the length

b

a b is twenty-two inches. The interior height of the furnace to

the opening where the ore is thrown in, is three ells and a

half from the stone on which the fire is built. The furnaces

at Schönfeld, however, are narrower, the anterior part (a a) is

only six inches wide, and the posterior nine inches, the length

(a b) is said to amount only to thirteen inches. The reason,

they say, is that the vein comes from the nucleus or the centre,

or from the Stockwerk, which requires a narrower place or

furnace. Then commences the chimney, which first is wider,

but afterwards, under the roof, narrower. Fig. 1 is the an

terior and external view ofthe furnace; c is the opening through

which the liquid metal con

tinually flows out; d is the

receptacle (tigillum) into which

the tin flows in a continual

stream; b is the place into

which the scoriæ are raised,

and thence thrown into water

and afterwards pulverized.

When the receptacle d is full,

the opening e is penetrated, and the metal is let out into the

excavation f which is in the floor, and which is made in the

solid rock. Fig. 2 is the side view of the furnace ; h is the

upper part of the furnace; ik the place where the pulverized

ore together with the charcoal is introduced ; I m is an oblong

trough or box where the pulverized ore is stored, and upon

.

which the person stands who throws in the ore and the char

coal. On the opposite side to that sketched in fig. 1 are the

bellows with the blast-hole.

Fig. 1. Fig. 2.

h

With respect to the introduction of the metal, there is no

constant rule as to time for all places. Generally the ore is

filled in four times every quarter of an hour, thus sixteen

times every hour. In other places it is scarcely filled in twelve

times, when the ore is poor, or difficult to melt, and when

<< prev. page << föreg. sida << >> nästa sida >> next page >>