Full resolution (JPEG) - On this page / på denna sida - The Öresund Power Cable of 1958, by Anders Bergman, Wilhelm Carlshem and Gottschalk von Geijer

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

extremely severe winters, however, the straits may

he filled by pack-ice. As a protection the cable is

provided with a very effective shore protection.

To facilitate the raising of the cable if repairs

should become necessary at some future date, it has

been laid with a certain excess length or slack. An

ample slack also is of importance with an uneven

bottom profile as it allows the cable to lie close

against the bottom. The cable-laying ship was

obliged to sail over a zig-zag course in order to pay out

the required excess length of cable. This presented

a somewhat difficult problem in navigation on

account of the strong current flowing in the straits.

Choice of a cable-laying ship

Cable-laying ships are usually employed for laying

submarine cables. These vessels are constructed with

special tanks in which the cable is stored in coils.

From the tanks the cable is paid out over a capstan

from the stern of the vessel. In this method of laying

the cable is subjected to torsion, and as the space

in the tanks is limited the cable coils will necessarily

be somewhat small. Since, moreover, the bottom in

this case is very shallow for some distance from

the shore and cable-laying ships have a fairly deep

draft the conventional method of laying was found

unsuitable here also. A floating drum designed for

laying power cables was produced by the Nordiske

Kabel- og Traadfabriker at the beginning of the

1950s. The owners kindly placed this floating drum

at the disposal of Sieverts Kabelverk, which firm

was entirely responsible for the actual laying. The

appearance of the drum is illustrated in fig. 4. The

carrying capacity of the drum is approximately 250

tons of cable and the draft at this load is about

5.2 m. The drum has a diameter of 6 metres.

Telecommunication system during laying

When laying out the cable a rapid system of

intercommunication must be available, primarily,

between the floating drum and the tugboat and also

between the respective shores and the tugboat. A

station mounted in a motor vehicle was employed

on the Swedish shore, whereas portable radio sets

were used on the Danish shore and also on the

tugboat and floating drum. The radio system

operated in the 36 and 75 MHz bands with simplex

telephony.

Navigation

The Danish Decca chain was used as an aid to

navigation in laying the cable. The Decca receiver

on board the main tugboat was equipped with a

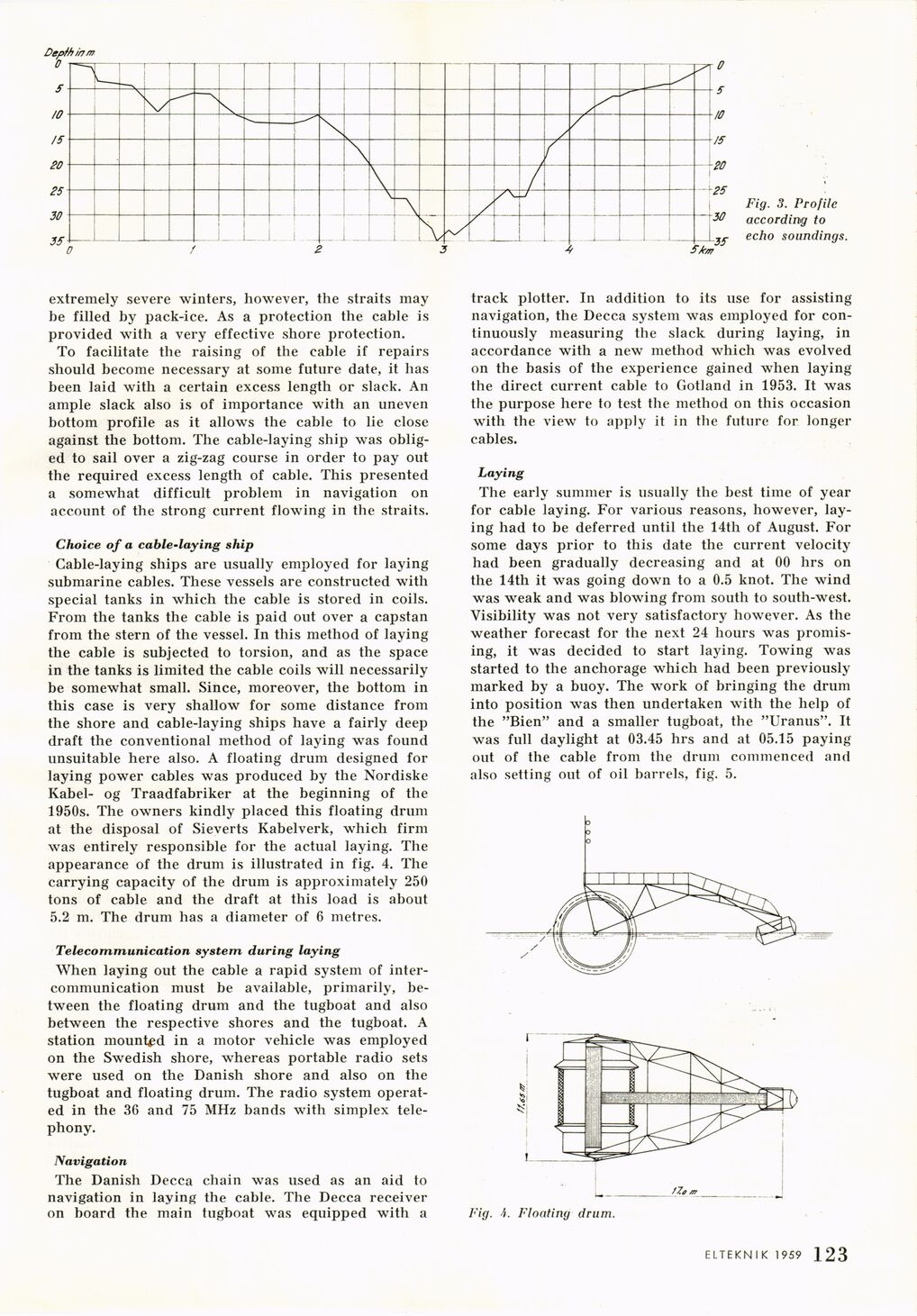

Fig. 3. Profile

according to

echo soundings.

track plotter. In addition to its use for assisting

navigation, the Decca system was employed for

continuously measuring the slack during laying, in

accordance with a new method which was evolved

on the basis of the experience gained when laying

the direct current cable to Gotland in 1953. It was

the purpose here to test the method on this occasion

with the view to apply it in the future for longer

cables.

Laying

The early summer is usually the best time of year

for cable laying. For various reasons, however,

laying had to be deferred until the 14th of August. For

some days prior to this date the current velocity

had been gradually decreasing and at 00 hrs on

the 14th it was going down to a 0.5 knot. The wind

was weak and was blowing from south to south-west.

Visibility was not very satisfactory however. As the

weather forecast for the next 24 hours was

promising, it was decided to start laying. Towing was

started to the anchorage which had been previously

marked by a buoy. The work of bringing the drum

into position was then undertaken with the help of

the "Bien" and a smaller tugboat, the "Uranus". It

was full daylight at 03.45 hrs and at 05.15 paying

out of the cable from the drum commenced and

also setting out of oil barrels, fig. 5.

Fig. A. Floating drum.

ELTEKNIK 1959 1 123

<< prev. page << föreg. sida << >> nästa sida >> next page >>