Full resolution (JPEG) - On this page / på denna sida - Strength of Materials - Factor of safety - Notes on strength of materials

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

274 STRENGTH OF MATERIALS.

FACTOR OF SAFETY.

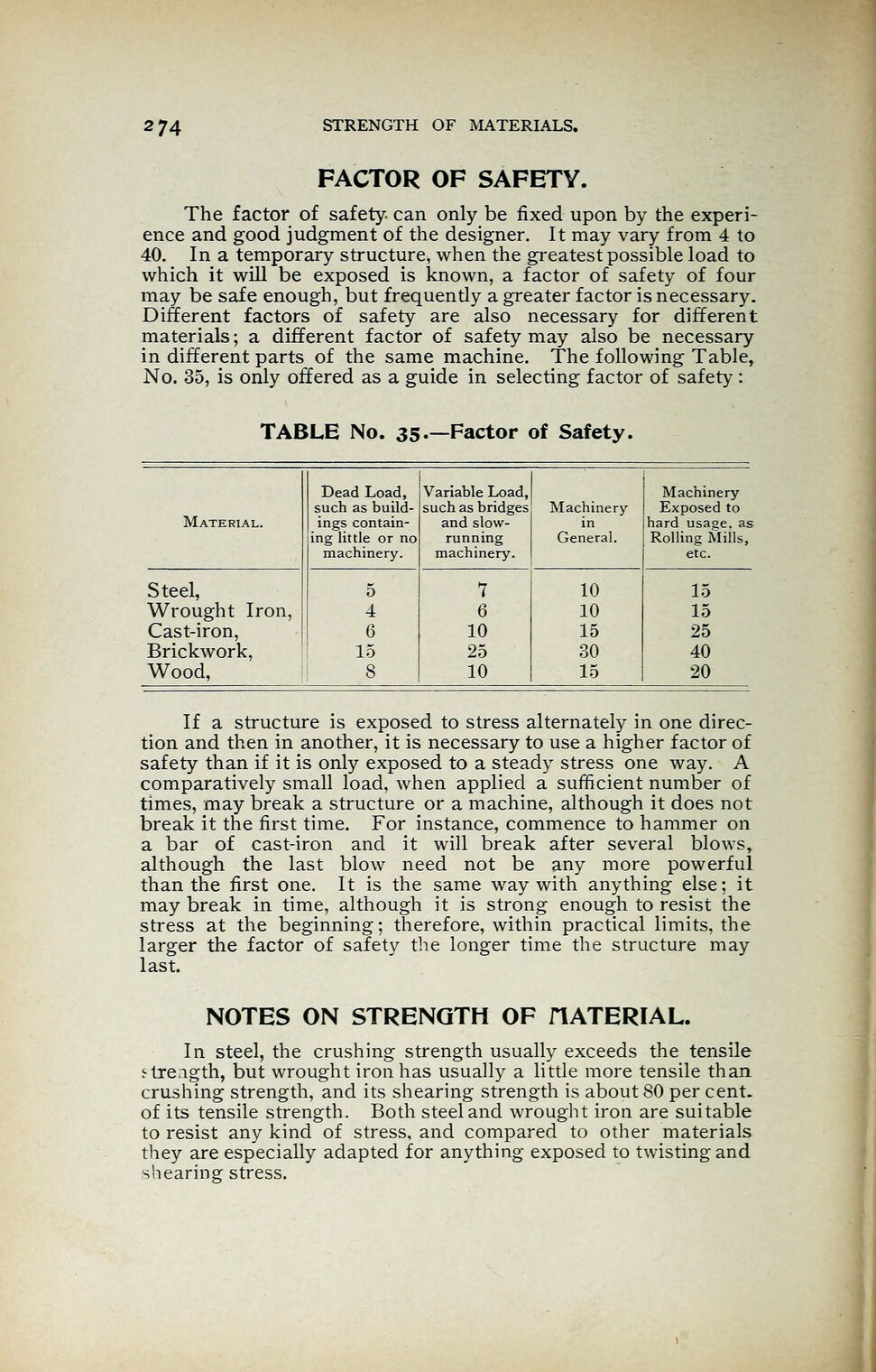

The factor of safety- can only be fixed upon by the experi-

ence and good judgment of the designer. It may vary from 4 to

40. In a temporary structure, when the greatest possible load to

which it will be exposed is known, a factor of safety of four

may be safe enough, but frequendy a greater factor is necessary.

Different factors of safety are also necessary for different

materials ; a different factor of safety may also be necessary

in different parts of the same machine. The following Table,

No. 35, is only offered as a guide in selecting factor of safety

:

TABLE No. 35.—Factor of Safety.

Dead Load, Variable Load, Machinery

such as build- such as bridges Machinery Exposed to

Material. ings contain- and slow- in hard usage, as

ing little or no running General. Rolling Mills,

machinery. machinery. etc.

Steel, 5 7 10 15

Wrought Iron, 4 6 10 15

Cast-iron, 6 10 15 25

Brickwork, 15 25 30 40

Wood, 8 10 15 20

If a structure is exposed to stress alternately in one direc-

tion and then in another, it is necessary to use a higher factor of

safety than if it is only exposed to a steady stress one way. A

comparatively small load, when applied a sufficient number of

times, may break a structure or a machine, although it does not

break it the first time. For instance, commence to hammer on

a bar of cast-iron and it will break after several blows,

although the last blow need not be any more powerful

than the first one. It is the same way with anything else; it

may break in time, although it is strong enough to resist the

stress at the beginning ; therefore, within practical limits, the

larger the factor of safety the longer time the structure may

last.

NOTES ON STRENGTH OF HATERIAL.

In steel, the crushing strength usually exceeds the tensile

Kxeiigth, but wrought iron has usually a little more tensile than

crushing strength, and its shearing strength is about 80 per cent,

of its tensile strength. Both steel and wrought iron are suitable

to resist any kind of stress, and compared to other materials

they are especially adapted for anything exposed to twisting and

shearing stress.

<< prev. page << föreg. sida << >> nästa sida >> next page >>