Full resolution (JPEG) - On this page / på denna sida - Shafting - Shafts for idlers - Proportions of keys

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

3^8 SHAFTING.

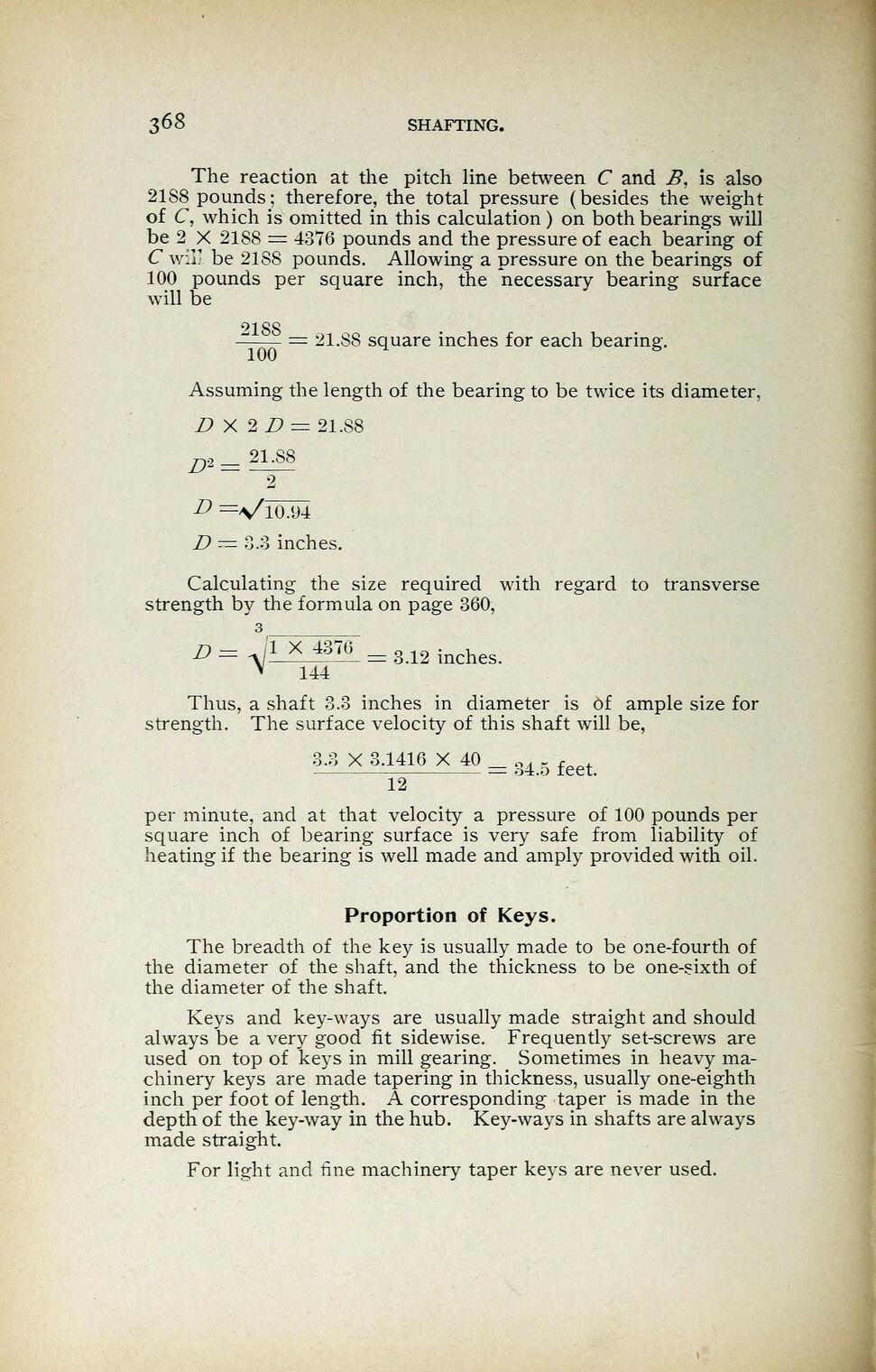

The reaction at the pitch line between C and B, is also

21S8 pounds; therefore, the total pressure (besides the weight

of C, which is omitted in this calculation ) on both bearings will

be 2 X 2188 = 4376 pounds and the pressure of each bearing of

C wil« be 2188 pounds. Allowing a pressure on the bearings of

100 pounds per square inch, the necessary bearing surface

will be

91 go

— = 21.S8 square inches for each bearing.

Assuming the length of the bearing to be twice its diameter,

D X 2 D = 21.88

^21^8

2

D =Vio.y4

D — o.3 inches.

Calculating the size required with regard to transverse

strength by the formula on page 360,

3

D = A/

1 X 4376

_ = 3.12 inches.

144

Thus, a shaft 3.3 inches in diameter is Of ample size for

strength. The surface velocity of this shaft will be,

3.3X3.1416X40 ^,^

12

per minute, and at that velocity a pressure of 100 pounds per

square inch of bearing surface is very safe from liability of

heating if the bearing is well made and amply provided with oil.

Proportion of Keys.

The breadth of the key is usually made to be one-fourth of

the diameter of the shaft, and the thickness to be one-sixth of

the diameter of the shaft.

Keys and key-ways are usually made straight and should

always be a very good fit sidewise. Frequently set-screws are

used on top of keys in mill gearing. Sometimes in heavy ma-

chinery keys are made tapering in thickness, usually one-eighth

inch per foot of length. A corresponding taper is made in the

depth of the key-way in the hub. Key-ways in shafts are always

made straight.

For light and fine machinery taper keys are never used.

<< prev. page << föreg. sida << >> nästa sida >> next page >>