Full resolution (JPEG) - On this page / på denna sida - Gear Teeth - Cutting bevel gears - Worms and worm gears

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

BEVEL GEARS. 403

the large end, although it may be necessary to round the teeth

a little, outside the pitch line on the small end, by filing.

Of course, a spur gear cutter cannot be used for cut-

ting bevel gears, because, although it may have the correct

curve, it would be too thick. The thickness of a bevel gear

cutter must be at least 0.005 inch thinner than the space be-

tween the teeth at their small end.

Large bevel gears are made on theoretically correct prin-

ciples by planing on specially constructed machines.

WORMS AND WORM GEARS.

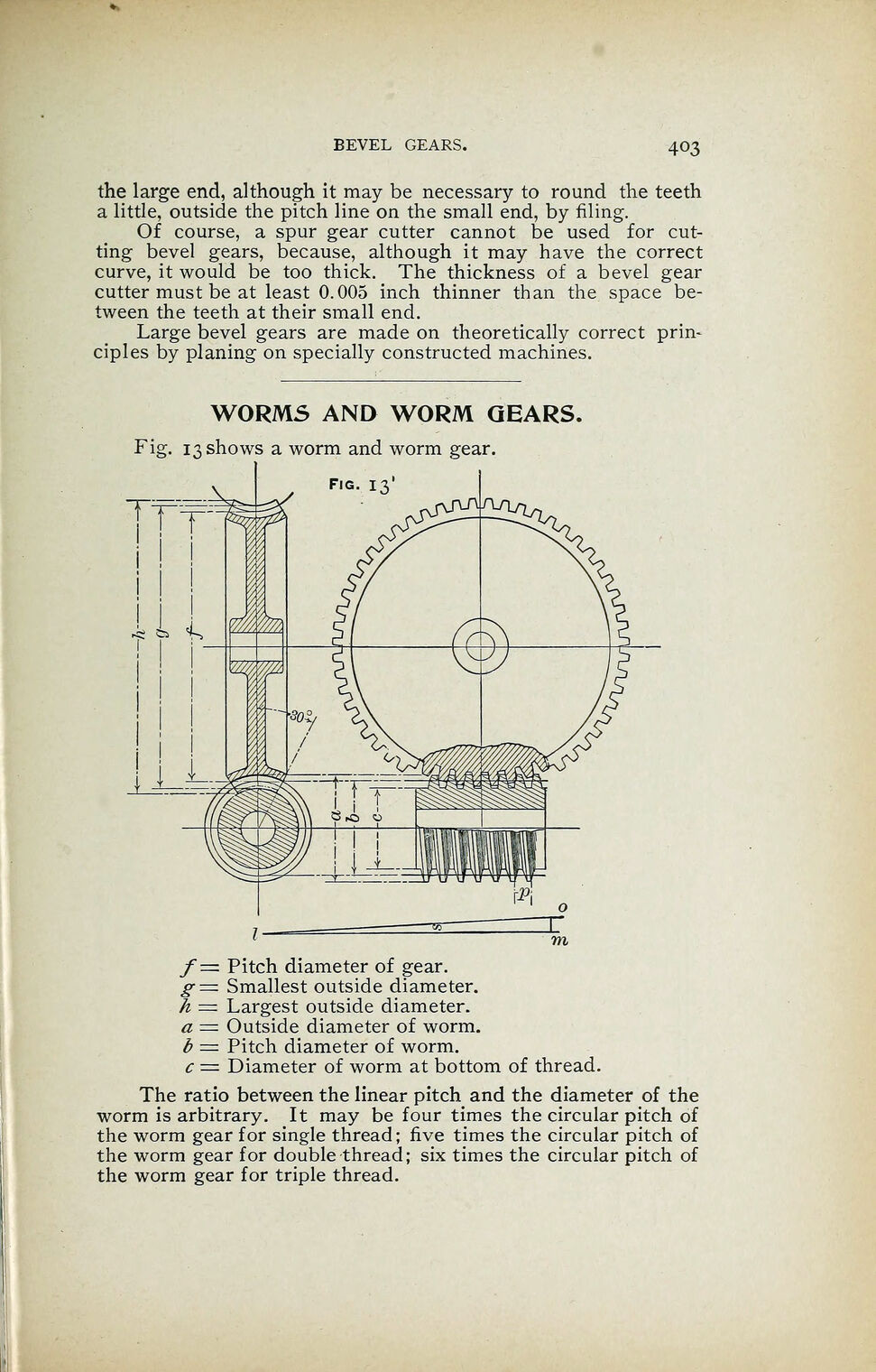

13 shows a worm and worm gear.

Fig. 13’

/"= Pitch diameter of gear.

g-= Smallest outside diameter.

h = Largest outside diameter.

a = Outside diameter of worm.

b = Pitch diameter of worm.

c = Diameter of worm at bottom of thread.

The ratio between the linear pitch and the diameter of the

worm is arbitrary. It may be four times the circular pitch of

the worm gear for single thread; five times the circular pitch of

the worm gear for double thread; six times the circular pitch of

the worm gear for triple thread.

<< prev. page << föreg. sida << >> nästa sida >> next page >>