Full resolution (JPEG) - On this page / på denna sida - Pipes - Wrought iron pipes

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

44Q

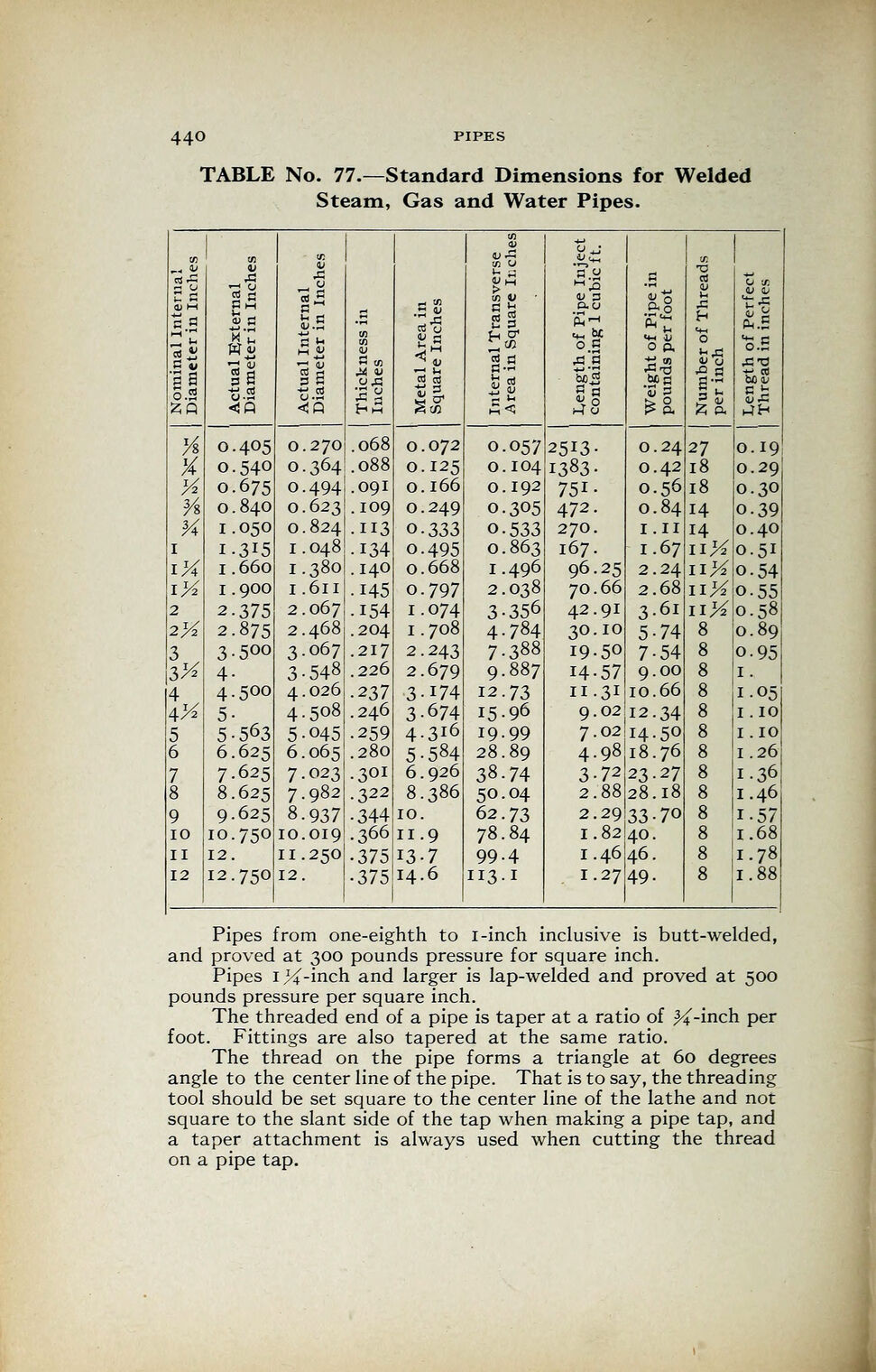

TABLE No. 77.—Standard Dimensions for Welded

Steam, Gas and Water Pipes.

V.

0> M

to

U

_

n

- X

<v

tn

>

ft

to

•v

ca

V

u

X.

s.

flu

V)

IB

co cj

<

^ u

Sec

2§

c

S 12

ft

b>

1- j2

P-I.5

o.5

"3 a

5.2

"2 w "3 ^ 5-H

As

J-Jcj

-G S3

II

^ 0.405 O.270 .O68 O.O72 0.057 25I3. 0.24 27 0.19

X 0.540 O.364 .088 O.I25 0.104 1383. 0.42 18 0.29

X O.675 O.494 .091 O. 166 0.192 75* • 0.56 18 0.30

H O.840 O.623. 109 0.249 0.305 472. 0.84 14 0.39

X I.050 O.824 .113 0.333 0.533 270. 1. 11 14 0.40

1 1. 315 I.048 .134 0.495 0.863 167. 1.67 nX 0.51

iX I.660 1. 380I. 140 O.668 1.496 96.25 2.24 IIX 0.54

iK I.900 1. 6ll .145 0.797 2.038 70.66 2.68 nx 0.55

2 2.375 2. 067!. 154 1.074 3.356 42.91 3.61 nx 0.58

2K 2.875 2.468 .204 1.708 4.784 30.10 5-74 8 0.89

3 3-500 3.067 •217 2.243 7.388 19-50 7-54 8 0.95

3K 4- 3-548 .226 2.679 9.887 14.57 9.00 8 I

.

4 4.500 4.O26 .237 3.174 12.73 11. 31 10.66 8 1.05

4K 5- 4.508 .246 3-674 15.96 9.02 12.34 8 1 .10

5 5-563 5-045 •259 4-316 19.99 7.02 14-50 8 1. 10

6 6.625 6.065 .280 5-584 28.89 4.98 18.76 8 1.26

7 7.625 7.023 .301 6.926 38.74 3-72 23.27 8 1-36;

8 8.625 7.982 .322 8.386 50.04 2.88 28.18 8 1 .46

9 9.625 8.937 •344 10. 62.73 2.29 33 -70 8 1.57

10 10.750 10.019 .366 11.

9

78.84 1.82 40. 8 1.68

11 12. 11.250 •375 13-7 99-4 1.46 46. 8 1.78

12 12.750 12. .375I4-6 113.

1

1.27 49- 8 1.88

Pipes from one-eighth to i-inch inclusive is butt-welded,

and proved at 300 pounds pressure for square inch.

Pipes iX-inch and larger is lap-welded and proved at 500

pounds pressure per square inch.

The threaded end of a pipe is taper at a ratio of X-inch per

foot. Fittings are also tapered at the same ratio.

The thread on the pipe forms a triangle at 60 degrees

angle to the center line of the pipe. That is to say, the threading

tool should be set square to the center line of the lathe and not

square to the slant side of the tap when making a pipe tap, and

a taper attachment is always used when cutting the thread

on a pipe tap.

<< prev. page << föreg. sida << >> nästa sida >> next page >>