Full resolution (JPEG) - On this page / på denna sida - N:o 12. Dec. - Sidor ...

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

SKF BEARINGS IN THE AUTOMOBILE

The application of S K F bearings for

general engineering purposes is accompanied

by a technical service which carries

considerable weight with an engineer not fully

conversant with the principles involved. The

situation with regard to automobile work however, is

rather different. Many designers can look back

upon twenty years’ experience of anti-friction

bearings and their views on the selecting, fitting,

and maintenance of them have become settled

convictions.

This knowledge of the subject, strangely enough,

is not accompanied by a really intimate

acquaintance with the stresses present in ball or roller

bearings, and in addition it is very rare to find an

Automobile Drawing Office in which there is any

record of load analysis having been carried out.

The layout of a new chassis simply involves a

painstaking overhaul of all available information

regarding similar designs, and practice, in short,

is the guide to bearing selection as it is to the

settlement of many other points.

It has long been appreciated by S K F that the

selection of ball bearings on a basis of the

maximum load at the ruling speed without reference

to the fatigue factor is inadmissible. The bearings

would be altogether too costly. The qualification

by fatigue has, however, been on a purely

practical basis, and SKF research in this direction has

lifted the entire subject to a higher level of

treatment altogether. British practice was originally

based on a combination of ball and roller

construction of generous dimensions, all side shocks and

continuous thrusts being handled by thrust

bearings. The increasing confidence of the American

designer in the double purpose unit has so far not

found its reflection in the factories in England,

but there is every evidence that the work of S K F,

the last 12 months in this direction, will bear

excellent fruit.

SKF can point to an imposing array of

high-class British Cars in which our products have

found a field, but the general stagnation in

business has made it more imperative than ever to

observe costs. Our campaign has consequently

been directed with the object of giving the

maximum technical service with its accompanying

financial expression. The chassis layout is

obtained and promptly analysed by the Technical

Department, the result being a complete statement

of the loads at every point of application, and the

factors of safety with reference to our catalogue

ratings. The possibility of eliminating thrust

bearings in the differential or elsewhere is carefully

reviewed and the final estimate for the bearings

frequently shows an attractive reduction in capital

outlay.

The basis of this work has been a careful

overhaul of a large number of representative chassis

from which were graphed the factors of safety

with the existing design bearings which have given

satisfaction. These factors were brought into line

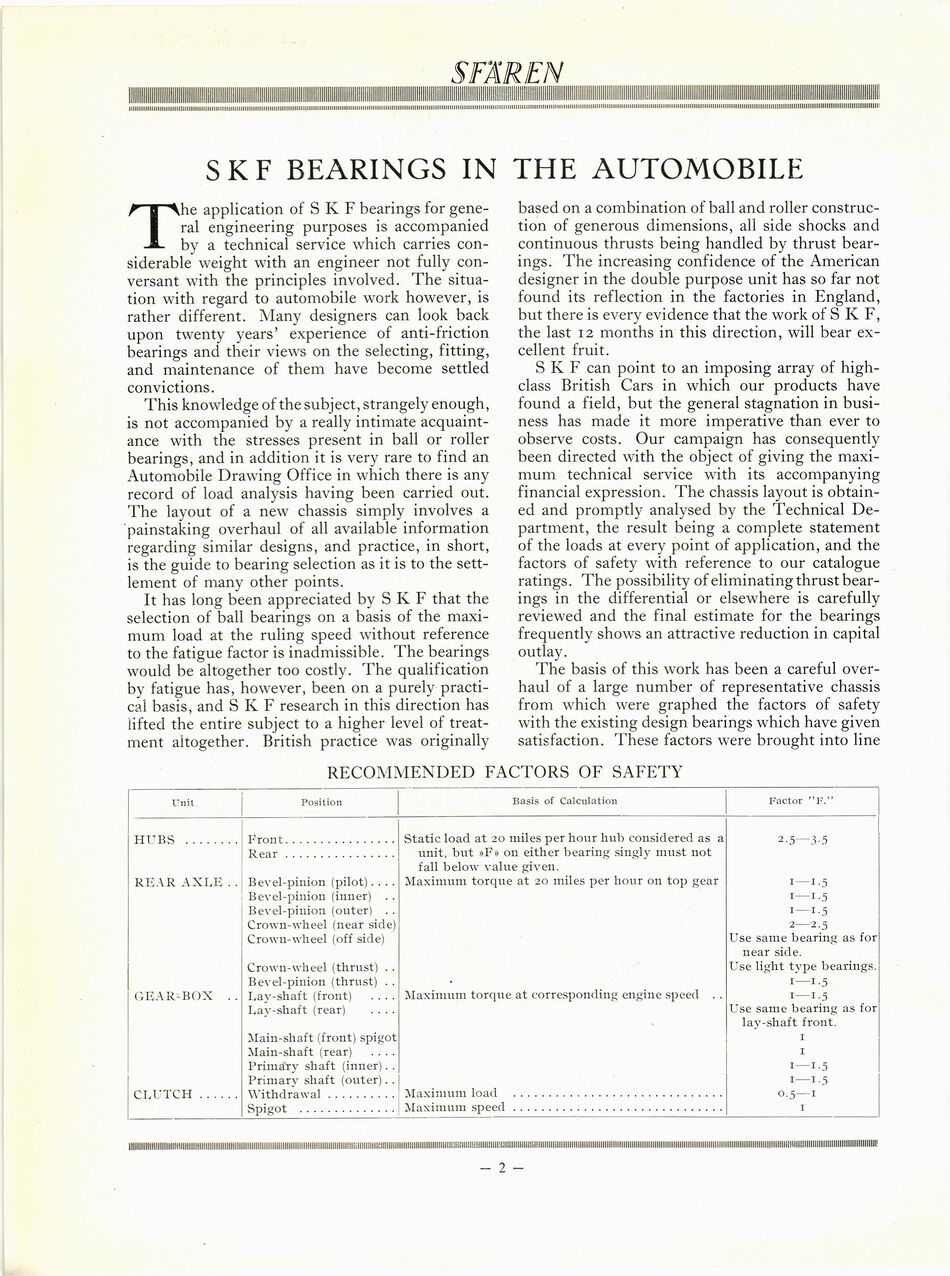

RECOMMENDED FACTORS OF SAFETY

Unit I Position Basis of Calculation Factor "F."

HUBS ........ Front................................Static load at 20 miles per hour hub considered as a 2.5—3.5

Rear................................unit, but »F» on either bearing singly must not

fall below value given.

REAR AXLE . . Bevel-pinion (pilot).... Maximum torque at 20 miles per hour on top gear 1—1.5

Bevel-pinion (inner) . . 1—1.5

Bevel-pinion (outer) .. 1—1.5

Crown-wheel (near side) 2—2.5

Crown-wheel (off side) Use same bearing as for

near side.

Crown-wheel (thrust) . . Use light type bearings.

Bevel-pinion (thrust) .. • 1—1.5

GEAR-BOX .. Lay-shaft (front) .... Maximum torque at corresponding engine speed .. 1—1.5

Lay-shaft (rear) .... Use same bearing as for

lay-shaft front.

Main-shaft (front) spigot 1

Main-shaft (rear) .... 1

Primary shaft (inner).. 1—1.5

Primary shaft (outer).. 1—1.5

CLUTCH...... Withdrawal....................Maximum load ............................................................0.5—1

Spigot ............................Maximum speed ............................................................1

<< prev. page << föreg. sida << >> nästa sida >> next page >>