Full resolution (JPEG) - On this page / på denna sida - Fly Wheels - Centrifugal force in fly-wheel and pulleys

<< prev. page << föreg. sida << >> nästa sida >> next page >>

Below is the raw OCR text

from the above scanned image.

Do you see an error? Proofread the page now!

Här nedan syns maskintolkade texten från faksimilbilden ovan.

Ser du något fel? Korrekturläs sidan nu!

This page has never been proofread. / Denna sida har aldrig korrekturlästs.

FLY-WHEELS. 359

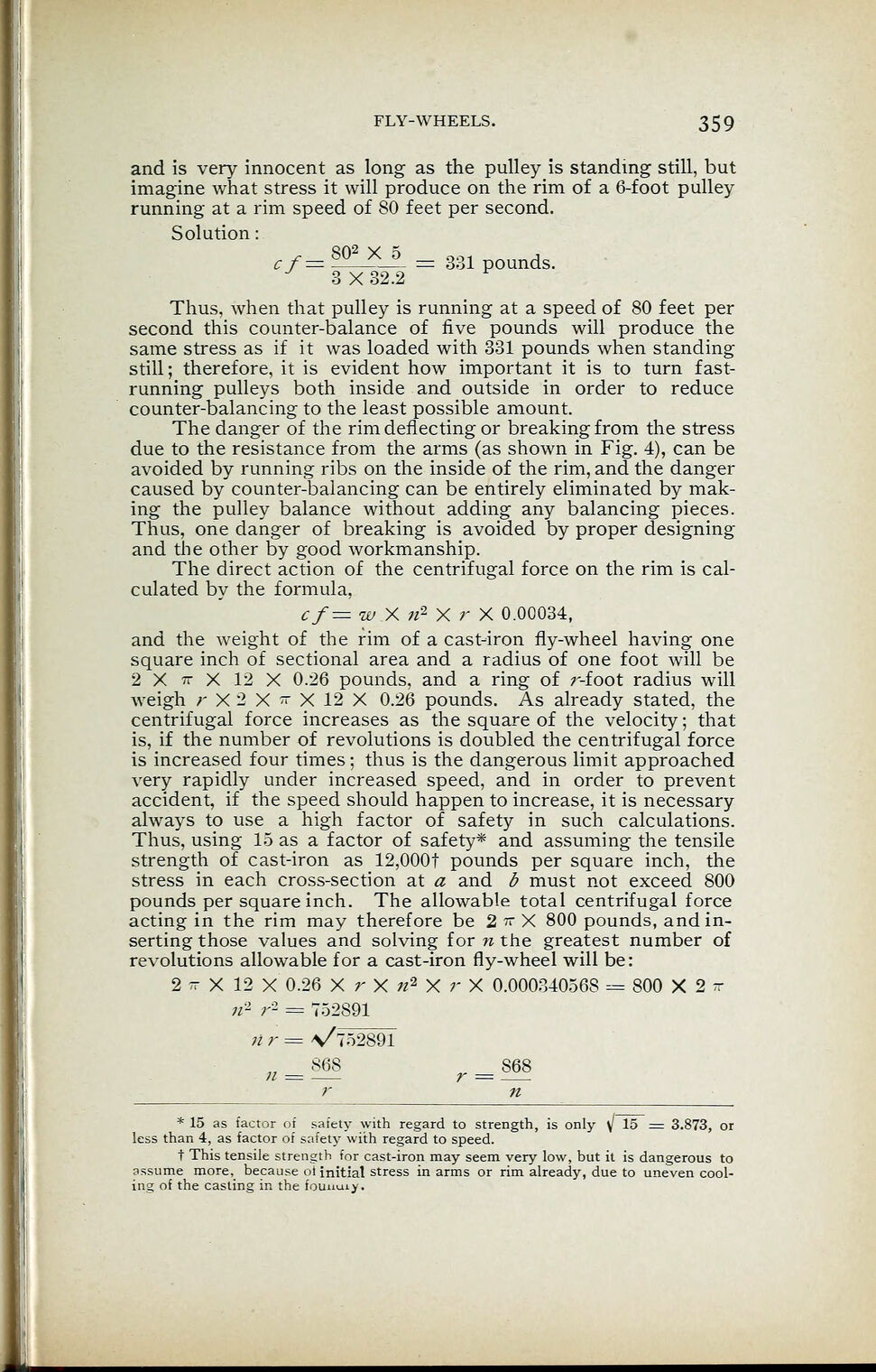

and is very innocent as long as the pulley is standing still, but

imagine what stress it will produce on the rim of a 6-foot pulley

running at a rim speed of 80 feet per second.

Solution:

cf= ^JiA = 331 pounds.

3 X 32.2

Thus, when that pulley is running at a speed of 80 feet per

second this counter-balance of five pounds will produce the

same stress as if it was loaded with 331 pounds when standing

still; therefore, it is evident how important it is to turn fast-

running pulleys both inside and outside in order to reduce

counter-balancing to the least possible amount.

The danger of the rim deflecting or breaking from the stress

due to the resistance from the arms (as shown in Fig. 4), can be

avoided by running ribs on the inside of the rim, and the danger

caused by counter-balancing can be entirely eliminated by mak-

ing the pulley balance without adding any balancing pieces.

Thus, one danger of breaking is avoided by proper designing

and the other by good workmanship.

The direct action of the centrifugal force on the rim is cal-

culated by the formula,

cf= w X if- X r X 0.00034,

and the weight of the rim of a cast-iron fly-wheel having one

square inch of sectional area and a radius of one foot will be

2 X re X 12 X 0.26 pounds, and a ring of r-foot radius will

weigh r X 2 X - X 12 X 0.26 pounds. As already stated, the

centrifugal force increases as the square of the velocity ; that

is, if the number of revolutions is doubled the centrifugal force

is increased four times ; thus is the dangerous limit approached

very rapidly under increased speed, and in order to prevent

accident, if the speed should happen to increase, it is necessary

always to use a high factor of safety in such calculations.

Thus, using 15 as a factor of safety* and assuming the tensile

strength of cast-iron as 12,000t pounds per square inch, the

stress in each cross-section at a and b must not exceed 800

pounds per square inch. The allowable total centrifugal force

acting in the rim may therefore be 2 n X 800 pounds, and in-

serting those values and solving for n the greatest number of

revolutions allowable for a cast-iron fly-wheel will be:

2 - X 12 X 0.26 X r X ;z

2

X r X 0.000340568 = 800 X 2 -

n1

r2

= 752891

n r = VT52891

;/ = 868

r = 868

r n

* 15 as factor of safety with regard to strength, is only y

1

15 = 3.873, or

less than 4, as factor of safety with regard to speed.

t This tensile strength for cast-iron may seem very low, but it is dangerous to

assume more, because oi initial stress in arms or rim already, due to uneven cool-

ing of the casting in the founuiy.

<< prev. page << föreg. sida << >> nästa sida >> next page >>